| VMA-T210X Twin Otter 09-15 ARF - (Stage 0) Wing Assembly - Joining the Wing Halves |

|

In some markets we have reduced the length of the shipping box by shipping the wing in two pieces in order to save end consumers from having to pay surcharges on freight. The Assembly and Operations Manual (version 20061031) does not include instructions for joining the wing halves.

If your wing was shipped in two pieces, BEFORE BEGINNING Stage 1 of the Assembly and Operations Manual please COMPLETE THE FOLLOWING "Stage 0" INSTRUCTIONS in order to assemble your wing.

|

| Parts Supplied:

- Right and left wing panels

- Wing joiner (also called dihedral brace)

- Roll of wing joint tape

|

Tools & Adhesives needed:

- 30 minute epoxy. Pacer Zepoxy #PAC-30ZPOXY8

recommended. (Do not use 5 Minute Epoxy)

- Epoxy brush or stir sticks

- Disposable mixing dish for the epoxy

- Sandpaper (Coarse 240 grit recommended)

- Low tack masking tape

- Pencil, knife and ruler

- Paper towels

|

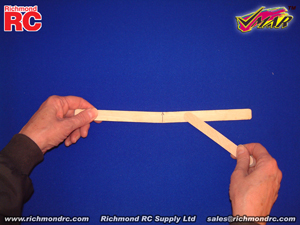

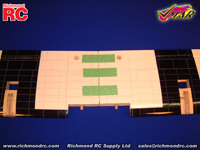

Step 0.1 Locate the wing joiner (also called Dihedral brace). Use a ruler, determine the center of the wing joiner and mark a center line with a pencil as illustrated in 0B.

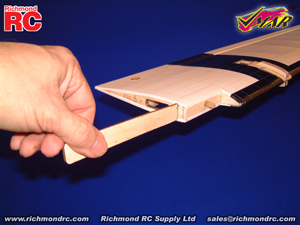

Step 0.2 Locate the wings (See 0A). Trial fit the wing joiner in the channels in the wing panels. You will see two channels in each wing. The channel closest to the leading edge should NOT be used. Insert the wing joiner into the channel that is slightly further aft in the wing. The wing joiner should insert smoothly up to the center line as illustrated in 0C.

Now slide the other wing panel onto the wing joiner until the panels meet. If the fit is overly tight, sand the wing joiner slightly and try again. Do not apply excessive force. Sand the joiner until a snug fit is obtained. If the panels slide onto the joiner relatively easily but you end up with a slight gap between the wing panels, trim the ends of the joiner by about 1/8 in. (3 mm) and try again. Work in small steps, testing the results between steps.

Mark the joiner to indicate which way is UP as illustrated in 0B.

|

|

|

|

|

0A - Left & right wing panels

|

0B - Preparation of wing joiner

|

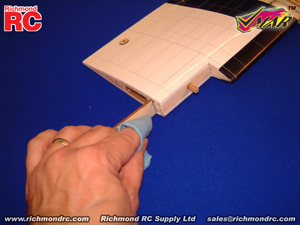

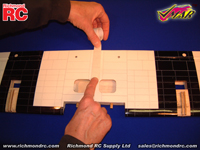

Step 0.3 Apply plenty of 30 minute epoxy to all sides of one end (half) of the wing joiner using a stir stick or epoxy brush as illustrated in 0D. Carefully insert the epoxy coated half of the wing joiner into one wing panel as illustrated in 0E.

See 0F and use a cloth or tissue to wipe away any excess epoxy that squeezes out of the joint.

Repeat this process several times to ensure the wing joiner and cavity are well coated with 30 minute epoxy.

When the wing joiner and cavity are well coated with 30 minute epoxy, insert the joiner to the center line, wipe way any excess epoxy and let dry. (Note: do not use 5 minute epoxy or CA to join the wings).

|

|

|

|

|

0C - Trial fit the wing joiner

|

0D - Apply plenty of 30 minute epoxy to the wing joiner

|

|

|

|

|

0E - Carefully insert the joiner all the way to the center line

|

0F - Wipe off the excess epoxy then allow to cure

|

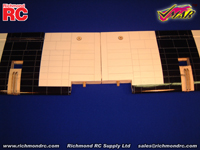

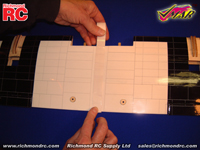

Step 0.4 When the epoxy holding the wing joiner into the first wing panel has cured, trial fit the second wing panel onto the wing joiner (do not glue without trial fitting first) to ensure that the two wing panels fit without an excessive gap.

Step 0.5 Now apply plenty of 30 minute epoxy to all sides of the exposed half of the wing joiner (see 0G). Use only 30 minute epoxy to ensure a strong bond and to give yourself plenty of working time. As described in step 0.3, repeatedly apply 30 minute epoxy to the joiner and insert the joiner into the wing joiner cavity to ensure that the wing joiner and the cavity are well coated with 30 minute epoxy.

When you have worked plenty of epoxy into the wing joiner cavity, pull the joiner out of the cavity one last time and apply plenty of 30 minute epoxy to the wing root ribs of both panels. Slide the wings together until the wing roots are firmly in contact with each other and there is no gap remaining between the wing panels (see OH). Epoxy should ooze from the joint and be cleaned off with a rag or tissue before it cures.

Step 0.6 Use low tack masking tape (see 0I) to align the wing surfaces and to hold the wing panels firmly together until the epoxy cures.

|

|

|

|

|

|

0G - Apply plenty of 30 minute epoxy to all surfaces.

|

0H - Align the two wing panels and slowly close the gap until the wing roots are firmly in contact with each other.

|

0I - Use low tack masking tape to hold the wing panels tightly together until the epoxy has completely cured.

|

Step 0.7 Once the epoxy has cured completely (allow several hours at least), the masking tape can be carefully removed from the wing panels. Peel the tape back on itself... do not pull upright away from the wing.

To seal and finish the joint between the wing panels, a roll of wing joint tape has been supplied. Starting on the bottom side of the wing, stick the tape centrally over the joint (see OJ) ensuring that the wing joint tape is pressed down firmly as you work around the wing. Wrap the wing joint tape all the way around the wing in one piece (see OK), starting and finishing on the bottom of the wing (see OL). Trim off any excess tape using a sharp knife.

|

|

|

|

|

|

0J - Apply wing joint tape over the joint starting here on the bottom.

|

0K - Continue applying the tape over the top of the wing, pressing down firmly as you go.

|

0L - Continue back around to the bottom of the wing & overlap the tape where you started. Trim off excess tape.

|

|

|

NEXT STEPS:

If you are installing a VMAX Power Pack or VMAX Power Module or VMAR Wiring Harness Set, please review the instructions that were supplied with these items now.

Otherwise once you have joined the wing halves, please proceed to Stage 1 of the Assembly and Operations Manual to continue with the assembly of your model.

|

|

Pictures are intended to illustrate components and methods of assembly. Production components may vary in detail from that shown.

|

|

|

|

|

|

|

|

|

|

| Article ID: 6756 |