a) Review the Read Me First documentation and the Assembly and Operations Manual that came with your model. Complete Stage 9 from the Assembly and Operations Manual using either a VMAX Power Module set, a VMAX Power Pack or third party motors and speed controllers.

b) After installation of your motors and speed controllers you may install the Power Wiring Harness. Locate the Power Wiring Harness parts bag and remove the harness.

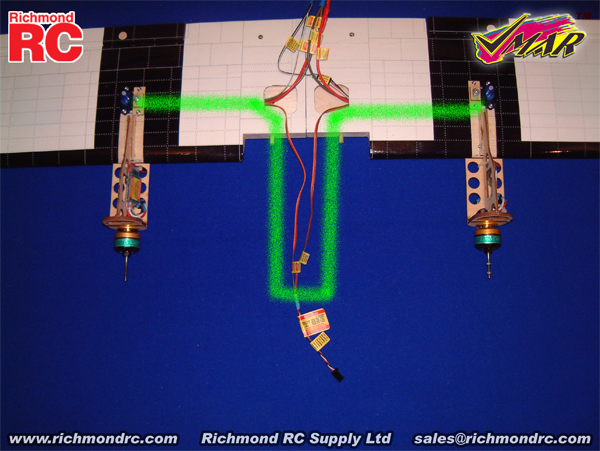

c) Read all labels attached to the Power Wiring Harness. Use 3A and the green "path" as a reference to guide you as you proceed with the installation.

|

|

|

3A - Power Wiring Harness Installed - Viewed from Top Side of Wing

|

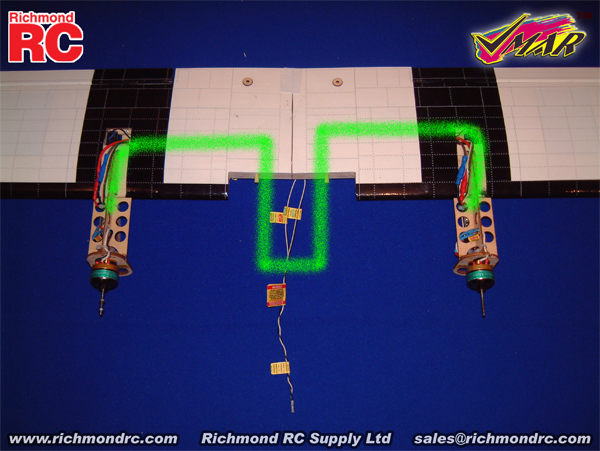

d) Turn the wing on its back so that you can see the two square access holes near the center of the wing. Support the center of the underside of the wing with a sheet of foam rubber or folded up fluffy towel.

e) Position the inverted wing so that the leading edge (thick) is closer to you and the trailing edge (thin) is further away. When oriented in this manner, the inverted wing panel on your left will be the left wing panel in flight and the inverted wing panel on your right will be the right wing panel in flight. This consistent definition of left and right makes it much easier to install the Power Wiring Harness properly.

f) Thread the end of the wire marked "+ Power + Positive Left" through the left square access hole near the center of the wing and through the internal wiring access tube to the left power access cavity located about 8.5 in. (215 mm) outboard from the center of the wing. Pull the loose end of the wire out of the tube so that it exits the downward facing surface of the wing through the left power access cavity. Connect the left speed control Red (+) lead to this wire. Gently pull the wire back from the source while routing the connected Red wire so that it lies neatly from the speed control and into the left power access cavity.

g) Repeat this process for the negative power connection to the left speed control. Thread the end of the wire marked "- Power - Negative Left" through the left square access hole near the center of the wing and through the internal wiring access tube to the left power access cavity located about 8.5 in. (215 mm) outboard from the center of the wing. Pull the loose end of the wire out of the tube so that it exits the downward facing surface of the wing through the left power access cavity. Connect the left speed control Black (-) lead to this wire. Gently pull the wire back from the source while routing the connected Black wire so that it lies neatly from the speed control and into the left power access cavity.

h) This completes the wiring of power to the left speed control.

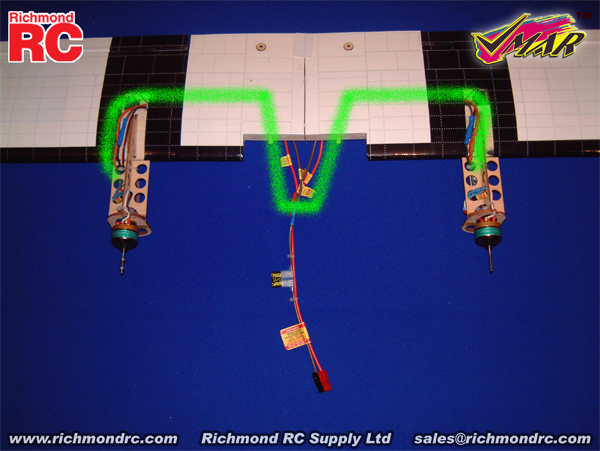

i) Now follow a similar process for the right speed control. Thread the end of the wire marked "+ Power + Positive Right" through the right square access hole near the center of the wing and through the internal wiring access tube to the right power access cavity located about 8.5 in. (215 mm) outboard from the center of the wing. Pull the loose end of the wire out of the tube so that it exits the downward facing surface of the wing through the right power access cavity. Connect the right speed control Red (+) lead to this wire. Gently pull the wire back from the source while routing the connected Red wire so that it lies neatly from the speed control and into the right power access cavity.

j) Repeat this process for the negative power connection to the right speed control. Thread the end of the wire marked "- Power -Negative Right" through the right square access hole near the center of the wing and through the internal wiring access tube to the right power access cavity located about 8.5 in. (215 mm) outboard from the center of the wing. Pull the loose end of the wire out of the tube so that it exits the downward facing surface of the wing through the right power access cavity. Connect the right speed control Black (-) lead to this wire. Gently pull the wire back from the source while routing the connected Black wire so that it lies neatly from the speed control and into the right power access cavity.

k) Once completed, the left and right speed control and motor assemblies will be connected to the Power Wiring Harness and the end of Power Wiring Harness with the square-like Black and Red connector will be hanging loose near the center of the wing ready to be plugged into your LiPo battery pack.