| 1. Wiring Harness Set - #VMA-T210XWHS For VMA-T210X Twin Otter - READ ME FIRST | PLEASE READ ME FIRST

BEFORE PROCEEDING TO ASSEMBLE OR OPERATE THIS PRODUCT

|

| LIABILITY DISCLAIMER & COPYRIGHT NOTICE | LIABILITY DISCLAIMER

The authors and/or suppliers and/or disseminaters of this information and/or product expressly disclaim any warranties or representations, either expressed or implied, including but not limited to implied warranties of fitness, accuracy, timeliness or applicability of the information and/or product provided here. In no event will the authors and/or suppliers and/or disseminaters of this information and/or product have any obligation arising from contract or tort, for loss of revenue or profit, or for indirect, special, incidental, consequential or other damages of any sort arising from this information and/or product. In using this information and/or product, the user accepts all responsibility for and all liability associated with such use.

PROCEEDING WITH THE USE OF THIS INFORMATION AND/OR PRODUCT INDICATES AGREEMENT WITH AND ACCEPTANCE OF THE LIABILITY DISCLAIMER.

|

| Please Note the following Caution | CAUTION

A Remote Control (RC) model aircraft is not a toy. It is a flying model that functions much like a full size airplane. If you do not assemble and operate model aircraft properly you can cause injury to yourself and others and damage property. DO NOT FLY a model aircraft unless you are qualified.

You are ultimately responsible for the mechanical, aeronautical and electrical integrity of any model you fly and all of the components that make up the model including but not limited to the airframe itself, control surfaces, hinges, linkages, covering, engine, motor, radio, servos, switches, wiring, battery and parts. Check all components before and after each flight. It is essential that you act with the clear understanding that you are solely responsible for all aspects of the model at all times. DO NOT FLY until it is right.

|

| 1.1. Wiring Harness Set - For VMA-T210X Twin Otter - General Information | |

|

| COPYRIGHT | Copyright Richmond RC Supply Ltd. All rights reserved.

|

| Tips for Avoiding Common Problems |

We have supplied thousands and thousands and thousands of model aircraft in the past 20 plus years. We're not bragging! We tell you this to give some credibility to our suggested list of tips that follow. In talking to modelers around the world, here is what we have found is the key to...

AVOIDING 90% of PROBLEMS that can arise:

- READ THE CAUTION ABOVE & READ THE LIABILITY DISCLAIMER.You are responsible for all aspects of any model you fly. You're It!

- READ ALL DOCUMENTATION before doing anything else!

- INSPECT CAREFULLY immediately upon arrival!.

- RETAIN ALL PACKAGING until the checkout is complete! If you need to return anything you must have all of the original packaging.

- READ & LOOK! At everything! Do it once & then do it again.

- REMEMBER WHAT "ARF" STANDS FOR. ARF means ALMOST Ready to Fly with an emphasis on ALMOST! Some assembly and modeling skills are required.

- ALLOW ENOUGH TIME to enjoy the assembly process! Rushing into a 6 hour job with 3 hours to spare simply will not work. This is a Hobby... take your time.

- DRY FIT & TEST ASSEMBLE EVERYTHING before you glue anything!

- USE 30 MINUTE EPOXY when joining wings & installing stabilizers and other structural components but only after you have dry fitted and test assembled the components without glue! Once parts are glued together they cannot be unglued and they cannot be returned or replaced without charge.

- PLAN AHEAD! BE CAREFUL! If you get into trouble, DON'T PANIC. Review everything again, talk it over with an experienced modeler and if still in difficulty consult our Support Services.

- TEST TEST!!! TUG TUG TUG!!! EVERYTHING... BEFORE & AFTER EACH FLIGHT! Your model may have been largely pre-constructed and may have pre-installed control rods, hinges, control surfaces and many other essential components. Hinges may have been pinned after they have been installed. However, you must double check every control surface and component before and after each flight. You and only you are responsible for the integrity of all components and the integrity of the model itself. Check everything before and after each flight. Tug on control surfaces, control rods, mounting bolts, T-nuts, mounting plates... tug on everything!

- DO NOT OVER TIGHTEN WING BOLTS or other fasteners. You want bolts and nuts snugly tight and if metal you can use a medium grade thread locker such as Pacer Z42 to help them stay tight. Fasteners must be snug and secure. However a model airplane is not a farm tractor or a garbage compactor. You do not need a pipe wrench or an electric drill to tighten up wing bolts or any other fastener. Leave your plumbing and power tools at home.. hand tools only and go easy on the torque... snug and secure... not stripped or torqued until they squeak or break. Wing bolts can take tremendous torque before breaking... but when you over tighten them or use an electric screw driver on a set of wing bolts, long before the bolts break you can fracture the fuselage, crack the mounting blocks or pull the heads of the bolts through the wing... these problems have a nasty habit of revealing themselves when you least expect the wing to fall off!

- DO NOT OVERPOWER ANY MODEL! Stay within the recommended power range for the model. If you overpower the model you run a high risk of structural failure that will lead to loss of control and a subsequent crash that will destroy the model and may cause injury and/or property damage.

- ASSUME NOTHING! Remember the old yarn about what happens when you ASS-U-ME something. Check everything repeatedly and frequently and DO NOT FLY any model unless you are satisfied that everything is in good working order.

|

| 1.2. Wiring Harness Set - For VMA-T210X Twin Otter - Introduction | |

Before beginning the Installation Instructions please read the Overview and check off the components provided. Each component is in a labelled parts bag. Please check off the components against the Contents list below. Leave the components in their parts bags for now. Do not remove the components from their parts bags until each is needed during the installation process.

|

| Wiring Harness Sets - For VMAR Power Packs - Overview | VMAR Wiring Harness Sets for VMAR Power Packs contain all of the wiring and connectors to install and operate the components of multi-motor VMAR Power Packs and any servos included with the power pack. ( Note: Single motor power systems include discrete wiring components and do not use a wiring harness "set" per se.)

VMAR Wiring Harness Sets are factory designed to fit into the applicable VMAR model with its applicable VMAR power system and any included servos. All of the connectors have been factory installed.

VMAR Wiring Harness Sets are:

- Included with VMAR Power Packs for the applicable model.

- Available as a stand alone accessory for use with VMAR Power Modules for the applicable model.

- Provide for fast and reliable installation of VMAR Power Packs and Power Modules into VMAR multi-motor electric models.

- Note: Modelers who are not experienced with multi-motor electric flight systems are strongly encouraged to use the VMAR Wiring Harness Set applicable to their VMAR multi-motor model. Scratch building and installing a reliable wiring harness set for a multi-motor electric model requires approximately 8 hours of work & considerable knowledge and experience.

- May be suitable for use with some third party power systems and servos supplied by end users.

|

| 1.3. Wiring Harness Set - For VMA-T210X Twin Otter - Contents | This VMAR Wiring Harness Set (WHS) contains the following

- Aileron Wiring Harness (WHA) to connect the two aileron servos in the wings to the aileron channel of the receiver in the fuselage. Total Length = approx 15 in. (380mm). Length from aileron channel connector to Y = approx 4 in. (102 mm)

- (Note: The aileron wiring harness does NOT provide for flaperon operation using a computer radio and two discrete receiver channels. VMAR models utilizing two aileron servos will usually support computer radio flaperon functionality in conjunction with the aileron wiring harness if additional aileron extensions are purchased in addition to the aileron wiring harness included with the wiring harness set).

- Throttle Wiring Harness (WHT) to connect two Electronic Speed Controls (ESC) to the throttle channel of the receiver in the fuselage. Total Length = approx 13 in. (330mm). Length from throttle channel connector to Y = approx 7 in. (178 mm)

- Power Wiring Harness (WHP) to provide Positive (+) and Negative (-) power to two motors from a single battery (fused in line). Total Length = approx 22.5 in. (570mm). Length from battery connector to Y = approx 9.25 in. (235 mm)

This VMAR Wiring Harness Set also contains:

- Elevator Wiring Harness (WHE) to connect the elevator servo located near the tail to the elevator channel of the receiver in the fuselage. Total Length = approx 23.5 in. (597 mm). Length from elevator channel connector to junction = approx 7 in. (178 mm)

- Rudder & Steering Wiring Harness (WHR) to connect the rudder servo located near the tail and the nose wheel steering servo to the rudder channel of the receiver in the fuselage. Total Length = approx 23.5 in. (597 mm). Length from rudder channel connector to Y = approx 7 in. (178 mm).

-

End User Wiring Labels

|

| 1.4. Wiring Harness Set - For VMA-T210X Twin Otter - Installation Instructions | |

Consult any labels carefully, particularly the larger WARNING labels. The labels are largely self explanatory. Reading the labels will save you a great deal of time and help prevent damage to your equipment.

|

| 1.4.1. Stage 1 - Install Aileron Wiring Harness (WHA) - For VMA-T210X Twin Otter |

a) Review the Read Me First documentation and the Assembly and Operations Manual that came with your model. Complete Stage 0 from the Read Me First document and Stage 1 from the Assembly and Operations Manual. Once completed you will have assembled the wing.

b) After assembly of the wing you may install the Aileron Wiring Harness. Locate the Aileron Wiring Harness parts bag and remove the harness.

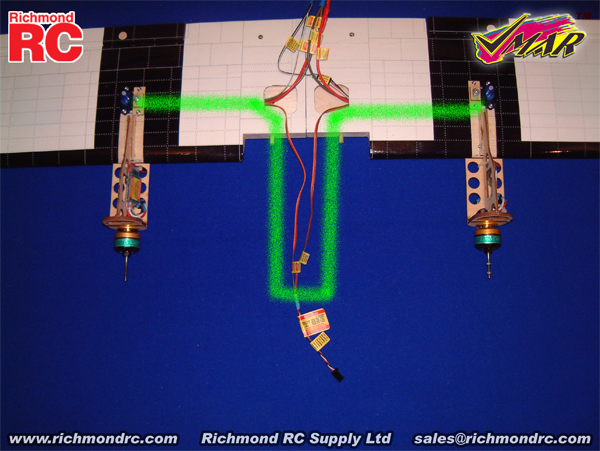

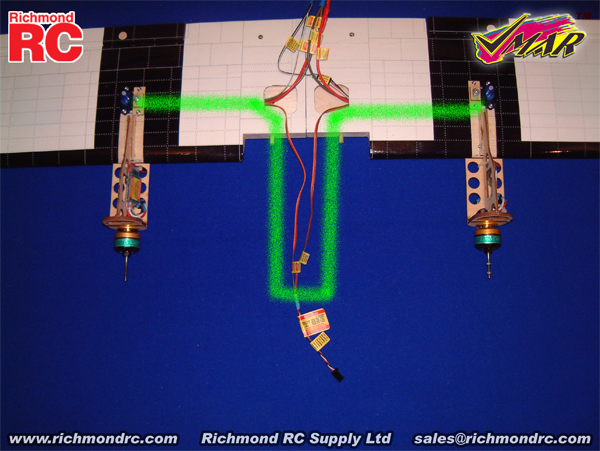

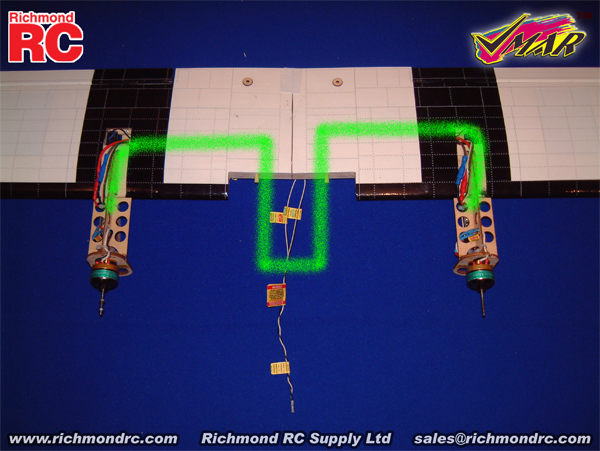

c) Read all labels attached to the Aileron Wiring Harness. Use 1A and the green "path" as a reference to guide you as you proceed with the installation.

|

|

|

1A - Aileron Wiring Harness Installed - Viewed from Bottom Side of Wing

|

d) Turn the wing on its back so that you can see the two square access holes near the center of the wing. Support the center of the underside of the wing with a sheet of foam rubber or folded up fluffy towel.

e) Position the inverted wing so that the leading edge (thick) is closer to you and the trailing edge (thin) is further away. When oriented in this manner, the inverted wing panel on your left will be the left wing panel in flight and the inverted wing panel on your right will be the right wing panel in flight. This consistent definition of left and right makes it much easier to install the aileron servos and aileron wiring harness properly.

f) Thread the end of the wire marked "Aileron Servo Left" through the left square access hole near the center of the wing and through the internal wiring access tube to the left aileron servo cavity located about 8.5 in. (215 mm) outboard from the center of the wing. Pull the loose end of the wire out of the tube so that it exits the upward facing bottom surface of the wing through the left servo cavity. Connect the left aileron servo to this wire. Use the supplied "Aileron Left" sticker to wrap the connection securely. Gently pull the wire back from the source and install the left aileron servo into position as shown in Stage 2 of the Assembly & Operations Manual.

g) Repeat this process for the wire marked "Aileron Servo Right", working with the right square access hole near the center of the wing and the internal wiring access tube that runs to the right servo cavity. Connect the right aileron servo to this wire. Use the supplied "Aileron Right" sticker to wrap the connection securely. Gently pull the wire back from the source and install the right aileron servo into position as shown in Stage 2 of the Assembly & Operations Manual.

h) Once completed, both aileron servos will be installed into the bottom of the wing and the end of the Aileron Wiring Harness that is labeled "Aileron Channel ==> ==>" will be hanging loose near the center of the wing ready to be plugged into the aileron channel of your receiver.

|

| 1.4.2. Stage 2 - Install Throttle Wiring Harness (WHT) - For VMA-T210X Twin Otter |

a) Review the Read Me First documentation and the Assembly and Operations Manual that came with your model. Complete Stage 9 from the Assembly and Operations Manual using either a VMAX Power Module set, a VMAX Power Pack or third party motors and speed controllers.

b) After installation of your motors and speed controllers you may install the Throttle Warning Harness. Locate the Throttle Wiring Harness parts bag and remove the harness.

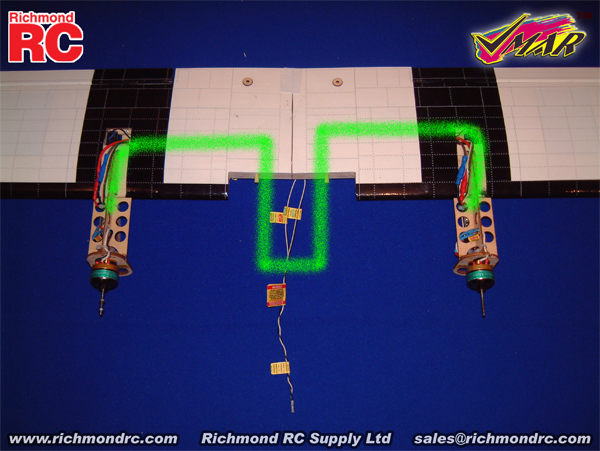

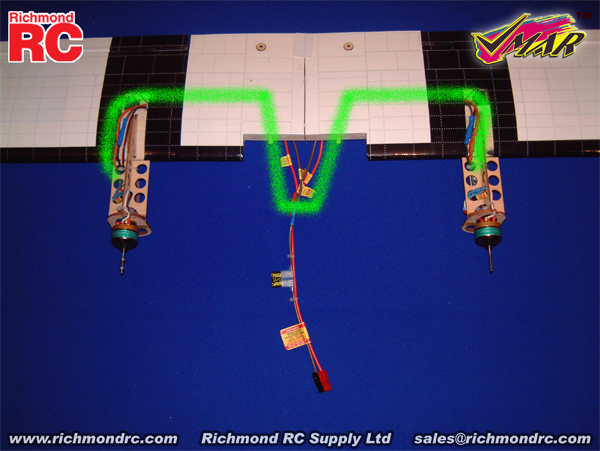

c) Read all labels attached to the Throttle Wiring Harness. Use 2A and the green "path" as a reference to guide you as you proceed with the installation.

|

|

|

2A - Throttle Wiring Harness Installed - Viewed from Top Side of Wing

|

d) Turn the wing on its back so that you can see the two square access holes near the center of the wing. Support the center of the underside of the wing with a sheet of foam rubber or folded up fluffy towel.

e) Position the inverted wing so that the leading edge (thick) is closer to you and the trailing edge (thin) is further away. When oriented in this manner, the inverted wing panel on your left will be the left wing panel in flight and the inverted wing panel on your right will be the right wing panel in flight. This consistent definition of left and right makes it much easier to install the Throttle Wiring Harness properly.

f) Thread the red, white and black wire lead from the left speed control into the power access cavity located on the downward facing surface of the left wing about 8.5 in. (215 mm) outboard from the center of the wing. Continue feeding the red, white and black wire from the cavity into and though the internal wiring access tube that runs to the left square access hole in the center of the wing. Gently pull the wire so that it protrudes from the left square access hole. Connect this protruding wire to the end of the Throttle Wire Harness marked "Throttle Control Left". Use the supplied "Throttle Left" sticker to wrap the connection securely.

g) Repeat this process for the right wing. Thread the red, white and black wire lead from the right speed control into the power access cavity located on the downward facing surface of the right wing about 8.5 in. (215 mm) outboard from the center of the wing. Continue feeding the red, white and black wire from the cavity into and though the internal wiring access tube that runs to the right square access hole in the center of the wing. Gently pull the wire so that it protrudes from the right square access hole. Connect this protruding wire to the end of the Throttle Wire Harness marked "Throttle Control Right". Use the supplied "Throttle Right" sticker to wrap the connection securely.

h) Once completed, both electronic speed controls will be connected to the Throttle Wiring Harness and the end of the Throttle Wiring Harness that is labeled "Throttle Channel ==> ==>" will be hanging loose near the center of the wing ready to be plugged into the throttle channel of your receiver.

|

| 1.4.3. Stage 3 - Install Power Wiring Harness (WHP) - For VMA-T210X Twin Otter |

a) Review the Read Me First documentation and the Assembly and Operations Manual that came with your model. Complete Stage 9 from the Assembly and Operations Manual using either a VMAX Power Module set, a VMAX Power Pack or third party motors and speed controllers.

b) After installation of your motors and speed controllers you may install the Power Wiring Harness. Locate the Power Wiring Harness parts bag and remove the harness.

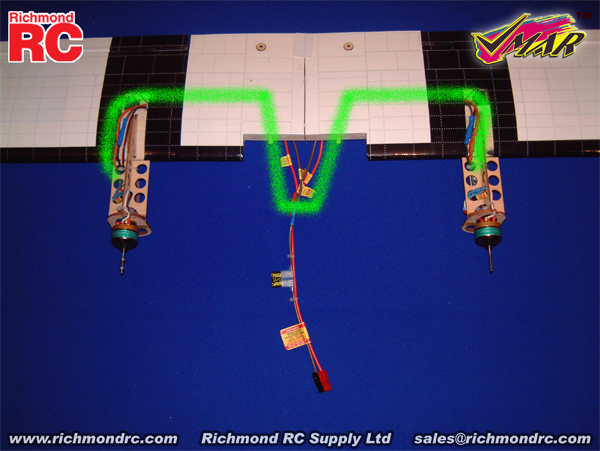

c) Read all labels attached to the Power Wiring Harness. Use 3A and the green "path" as a reference to guide you as you proceed with the installation.

|

|

|

3A - Power Wiring Harness Installed - Viewed from Top Side of Wing

|

d) Turn the wing on its back so that you can see the two square access holes near the center of the wing. Support the center of the underside of the wing with a sheet of foam rubber or folded up fluffy towel.

e) Position the inverted wing so that the leading edge (thick) is closer to you and the trailing edge (thin) is further away. When oriented in this manner, the inverted wing panel on your left will be the left wing panel in flight and the inverted wing panel on your right will be the right wing panel in flight. This consistent definition of left and right makes it much easier to install the Power Wiring Harness properly.

f) Thread the end of the wire marked "+ Power + Positive Left" through the left square access hole near the center of the wing and through the internal wiring access tube to the left power access cavity located about 8.5 in. (215 mm) outboard from the center of the wing. Pull the loose end of the wire out of the tube so that it exits the downward facing surface of the wing through the left power access cavity. Connect the left speed control Red (+) lead to this wire. Gently pull the wire back from the source while routing the connected Red wire so that it lies neatly from the speed control and into the left power access cavity.

g) Repeat this process for the negative power connection to the left speed control. Thread the end of the wire marked "- Power - Negative Left" through the left square access hole near the center of the wing and through the internal wiring access tube to the left power access cavity located about 8.5 in. (215 mm) outboard from the center of the wing. Pull the loose end of the wire out of the tube so that it exits the downward facing surface of the wing through the left power access cavity. Connect the left speed control Black (-) lead to this wire. Gently pull the wire back from the source while routing the connected Black wire so that it lies neatly from the speed control and into the left power access cavity.

h) This completes the wiring of power to the left speed control.

i) Now follow a similar process for the right speed control. Thread the end of the wire marked "+ Power + Positive Right" through the right square access hole near the center of the wing and through the internal wiring access tube to the right power access cavity located about 8.5 in. (215 mm) outboard from the center of the wing. Pull the loose end of the wire out of the tube so that it exits the downward facing surface of the wing through the right power access cavity. Connect the right speed control Red (+) lead to this wire. Gently pull the wire back from the source while routing the connected Red wire so that it lies neatly from the speed control and into the right power access cavity.

j) Repeat this process for the negative power connection to the right speed control. Thread the end of the wire marked "- Power -Negative Right" through the right square access hole near the center of the wing and through the internal wiring access tube to the right power access cavity located about 8.5 in. (215 mm) outboard from the center of the wing. Pull the loose end of the wire out of the tube so that it exits the downward facing surface of the wing through the right power access cavity. Connect the right speed control Black (-) lead to this wire. Gently pull the wire back from the source while routing the connected Black wire so that it lies neatly from the speed control and into the right power access cavity.

k) Once completed, the left and right speed control and motor assemblies will be connected to the Power Wiring Harness and the end of Power Wiring Harness with the square-like Black and Red connector will be hanging loose near the center of the wing ready to be plugged into your LiPo battery pack.

|

| 1.4.4. Stage 4 - Install Elevator Wiring Harness (WHE) - For VMA-T210X Twin Otter |

a) Review the Read Me First documentation and the Assembly and Operations Manual that came with your model. Complete Stage 12 from the Assembly and Operations Manual up to the point where your elevator servo is ready to install into the fuselage as illustrated in 12D.

b) Locate the Elevator Wiring Harness parts bag and remove the harness.

c) Read all labels attached to the Elevator Wiring Harness.

d) Remove the top hatch from the fuselage. Working from within the fuselage, pass the end of the wire labeled "Elevator Servo ==> ==>" back into the tail section of the fuselage and out through the elevator servo cavity on the right side of the fuselage near the tail.

e) Gently pull the wire so that it protrudes from the elevator servo cavity. Connect this protruding wire to the elevator servo. Use the supplied "Elevator" sticker to wrap the connection securely.

f) Working from within the fuselage gently pull the Elevator Wiring Harness forward toward the front of the fuselage and install the elevator servo into position as illustrated in picture 12E of the Assembly and Operations Manual.

g) Once completed, the elevator servo will be connected to the Elevator Wiring Harness and the end of the Elevator Wiring Harness that is labeled "Elevator Channel ==> ==>" will be hanging loose near the center of the fuselage ready to be plugged into the elevator channel of your receiver.

|

| 1.4.5. Stage 5 - Install Rudder & Steering Wiring Harness (WHR) - For VMA-T210X Twin Otter |

a) Review the Read Me First documentation and the Assembly and Operations Manual that came with your model. Complete Stage 12 from the Assembly and Operations Manual up to the point where your rudder servo is ready to install (but not yet installed) into the fuselage as illustrated in 12F.

b) Locate the Rudder & Steering Wiring Harness parts bag and remove the harness.

c) Read all labels attached to the Rudder & Steering Wiring Harness.

d) Remove the top hatch from the fuselage. Working from within the fuselage, pass the end of the wire labeled "Rudder Servo ==> ==>" back into the tail section of the fuselage and out through the rudder servo cavity on the left side of the fuselage near the tail.

e) Gently pull the wire so that it protrudes from the rudder servo cavity. Connect this protruding wire to the rudder servo. Use the supplied "Rudder" sticker to wrap the connection securely.

f) Working from within the fuselage gently pull the Rudder & Steering Wiring Harness forward toward the front of the fuselage and install the rudder servo into position as illustrated in picture 12F of the Assembly and Operations Manual.

g) Working from within the fuselage connect the wire "Nose Servo ==> ==>" to the nose gear steering servo as illustrated in pictures 20B, 20C and 21.2 of the Assembly and Operations Manual. Use the supplied "Steering" sticker to wrap the connection securely.

h) Once completed, the rudder servo and the nose gear servo will be connected to the Rudder & Steering Wiring Harness and the end of the Rudder & Steering Wiring Harness that is labeled "Rudder Channel ==> ==>" will be hanging loose near the center of the fuselage ready to be plugged into the rudder channel of your receiver.

|

| 1.5. Support | On Line, eMail, Fax, Phone, Mail

|

| We offer the Best in Support Services. | We back up our products and our customers with the best support services available. From our industry leading Knowledge Base to information about your Shipment, we've got you covered!

To access our Support Services please:

Your Choice of Support Services that Work for You:

|

| 1.5.1. Contact Us | For Sales and other Inquiries

|

| Support - Contact Us - Reach our Sales Department by eMail, Fax, Phone or Mail | Technical Inquiries: Please review the information provided in our Knowledge Base. After checking our Knowledge Base, if you need further assistance please use our Submit A Question service to get a response within 2 Business Days. Sales Inquiries: Please note that our Sales Department personnel are trained and dedicated to:

- Helping you with non-technical pre-purchase questions,

- Helping you place your order,

- Pointing out any sales, combos or specials that you may wish to consider,

- Inputting your order to our computer system so that it ships out as accurately and quickly as possible... usually the same day,

- Resolving any invoicing problems, and

- Helping to sort out any missing shipment or shipment damage issues.

Their depth of technical knowledge is about on par with what is shown in our printed sales literature. In most cases, they are working from the same printed advertisements or content from our web site that you are. Asking sales personnel to confirm the size, color and availability of a product is well within their capabilities. However, asking detailed questions about technical issues is not.

Buy our Products:

For All Other Inquiries... please consult the following resources:

- On Line Information

- On Line Support Services

- After reviewing our On Line resources, if you require additional assistance please contact us by eMail, fax, phone or mail as follows:

- Ask a Question

- eMail

- Fax

- Phone

- Mail

- Richmond RC Supply Ltd, #114 - 7350 72nd Street, Delta, BC, V4G-1H9

- Mail & printed correspondence only.

- We are not able to accomodate personal site visits or drop-offs/pick-ups at this location.

- Please note that all inbound Shipments require pre-Authorization in advance.

- Unauthorized inbound shipments will be refused.

|

| 1.6. Keep Up to Date | Check Frequently for Updates |

| Support - Stay Current - Check Frequently for Updated &/or Additional Information | This information is subject to change without notice. When viewing this information in a printed form the printing date will be visible in the lower right corner. Check frequently for updates &/or Additional Information.at www.richmondrc.com, > Enter the Site, > Support Services, follow the links to our Knowledge Base. Review the Table of Contents and search for the name and/or part number of this product.

For automated notification of changes to information contained in our Knowledge Base please register as a Priority Response member and subscribe to our Priority Response Notification Service.

|

|