| 1. Technical Information - VMAX Electric Power Systems - Product by Product | |

| 1.1. Batteries | Although there are a wide variety of different batteries, in our applications, batteries typically provide direct current (DC) power from the battery to a motor or other electrical component or circuit.

The output voltage and output current is important when selecting a battery. If the device you wish to power using a battery requires 12 Volts of Direct Current (VDC) as an input then you must choose a battery that provides 12 VDC output. The output current rating of the battery is also important. If your device requires 12 VDC at 10 Amps you must choose a 12 VDC battery that can safely supply 10 Amps or more.

A battery must be capable of providing the correct voltage for your device and it must be capable of providing at least the current that the device requires. A device that requires 12 VDC at 2 Amps will work fine with a battery rated for 12 VDC at 10 Amps but will not work with a 12 VDC battery that is rated capable of providing 1 Amp of current.

Never overload a battery or under power a device. You run the risk of damaging the battery and the device.

|

| 1.1.1. Battery Types - Chemistry & Characteristics |

| 1.1.2. VMAX Lithium Ion - A123 Nanophosphate | VMAX Lithium Ion Batteries use A123 Nanophosphate Cells.

Please consult the READ ME FIRST document supplied with your battery before using.

|

| 1.1.2.1. VMAX Lithium Ion - A123 Nanophosphate - READ ME FIRST |

|

BEFORE PROCEEDING

TO CHARGE OR

USE THIS BATTERY

|

|

PLEASE

READ ME FIRST

|

|

|

|

|

|

PLEASE

READ ME FIRST

|

|

BEFORE PROCEEDING

TO CHARGE OR

USE THIS BATTERY

|

|

|

|

|

|

| LIABILITY DISCLAIMER & COPYRIGHT NOTICE | LIABILITY DISCLAIMER

The authors and/or suppliers and/or disseminaters of this information and/or product expressly disclaim any warranties or representations, either expressed or implied, including but not limited to implied warranties of fitness, accuracy, timeliness or applicability of the information and/or product provided here. In no event will the authors and/or suppliers and/or disseminaters of this information and/or product have any obligation arising from contract or tort, for loss of revenue or profit, or for indirect, special, incidental, consequential or other damages of any sort arising from this information and/or product. In using this information and/or product, the user accepts all responsibility for and all liability associated with such use.

PROCEEDING WITH THE USE OF THIS INFORMATION AND/OR PRODUCT INDICATES AGREEMENT WITH AND ACCEPTANCE OF THE LIABILITY DISCLAIMER.

|

| 1.1.2.1.1. Think Safety | Power supplies, battery chargers, batteries, motors and related accessories, tools and equipment can be hazardous if improperly used. Be cautious and follow all safety recommendations when using this product. Keep hands, tools, clothing, liquids and all foreign objects and flammables well clear of equipment prior to and during operations. Check and double check all electrical connections before operating.

|

WARNING - FIRE RISK

If this product or any wire, cable, adapter or other device to which it is connected Overheats, Smokes, Smells or Swells then IMMEDIATELY UNPLUG all connections & MOVE ALL COMPONENTS to a Safe Outdoor Location.

Do NOT Overload, Short Circuit, Drop, Mechanically Damage or Immerse

Do NOT connect or operate Near Flammable Materials.

Do NOT operate inside an Automobile or other Vehicle.

Do NOT operate when Hot.

Do NOT operate in a wet environment.

Ensure that devices to which this product is connected have compatible voltage and current requirements.

UNPLUG WHEN UNATTENDED

|

|

| 1.1.2.1.2. VMAX Lithium Ion - A123 Nanophosphate - Introduction | Before proceeding please read the Overview and check off the components provided against the Contents list below. Leave the components in their packaging for now. Do not remove a component from it's packaging until it is needed.

|

| 1.1.2.1.3. VMAX Lithium Ion - A123 Nanophosphate - Contents | This VMAX Lithium Ion - A123 Nanophosphate battery consists of the following:

- The battery itself consisting of 1 or more A123 Nanophosphate cells

- Wiring and connectors supplied with and/or attached to the battery

- Documentation.

|

| 1.1.2.1.4. VMAX Lithium Ion - A123 Nanophosphate - Installation Instructions | Consult any labels carefully, particularly any WARNING labels. The labels are largely self explanatory. Reading the labels will save you a great deal of time and help prevent damage to your equipment.

Review carefully the following specifications printed on the battery:

Voltage - This is usually a multiple of 3.3. for example 3.3 Volts, 6.6 Volts, 9.9 Volts, 13.2 Volts etc. Ensure that the battery voltage is suitable for use with whatever you connect the battery to.

Capacity - This is stated in mAh for example 1100 mAh, 2300 mAh etc.

MAX CELL CURRENT - A123 Cells are capable of 30C continuous current and 60C current for up to 10 seconds. The actual 30C and 60C current values in Amps are stated on the battery. These values are large and they are correct for the cells themselves but the battery pack assembly should not be assumed to be able to provide current at these levels. Often the manufacturer of the connector or wiring or internal welding strips has lower maximum current values. Look for lower limits stated on the battery, for example "Connector rated for 45A". Ensure you test to ensure that your application does not exceed either the 30C rate or the third party component rating (such as the connector) whichever is lower.

MAX CHARGE - A123 Cells can be charged at up to the 5C rate. The actual 5C current value in Amps is stated on the battery. Make sure you do not exceed the MAX CHARGE current when charging. A123 cells perform best when balanced. The balancing voltage should not exceed 4.2V/cell. This is best done at a low current value such as 50mA or less.

Connectors:

If your battery was supplied with an output power connector such as an Anderson Power Pole or a Deans Connector we strongly suggest NOT changing the connector. If your intended application requires a different connector we suggest using an adapter to mate the battery to your device.

If your battery was supplied with output power wires only (no connector) you need to install your choice of connector:

-

We strongly encourage the use of Anderson Power Pole connectors using 45 Amp contacts professionally crimped into place or Deans connectors professionally soldered to the power wires of the battery.

-

Remove the insulation from only one wire at a time to avoid the wires every contacting each other. Contact will create a high current short circuit that can cause a fire and damage your battery.

-

Ensure that the red wire is joined to the positive (+) connector and the black wire is joined to the negative (-) connector. Incorrect polarity will damage the battery and devices to which the battery is connected and may cause a fire.

UNPLUG WHEN UNATTENDED. DO NOT SHORT CIRCUIT.

|

| 1.1.2.1.5. VMAX Lithium Ion - A123 Nanophosphate - Operating |

Powering Up - Turning On

A) Consult any labels carefully, particularly any WARNING labels. The labels are largely self explanatory. Paying attention to the labels will help prevent accidents and damage to your equipment.

B) Consult the documentation that came with the device you are going to connect your battery to.

- Ensure that the voltage of the battery is suitable for use with the device.

- Ensure that the current rating of the battery is suitable for use with the device.

- Ensure that the power output plug on the battery is compatible with the power input connector on the device. If not, we strongly suggest using an adapter rather than cutting connectors off and rewiring.

- Ensure you know how to turn the device on and off and what to watch for in the way of indicator lights etc.

C) Turn the device off before connecting the battery.

D) If the device has external moving parts such as a propeller, wheels, tires, shafts, gears etc ensure that the moving components are standing clear of any obstacles, hair or clothing. Be particularly careful to protect your eyes and fingers and the eyes and fingers of others. Ensure that the device cannot move if power is suddenly applied.

D) Connect the battery to the device.

E) Ensure that the device cannot move if power is suddenly applied. Turn on the device and operate the device through its full range of power settings.

STAY ALERT FOR OVERHEATING, SMELLS, SMOKE OR OTHER SIGNS OF TROUBLE. UNPLUG ALL CONNECTIONS IMMEDIATELY IF THE BATTERY OR ANY CORD OR DEVICE OVERHEATS, SMELLS, SMOKES, SPARKS OR MAKES ANY UNEXPECTED NOISE OR EMISSION AND REMOVE COMPONENTS TO A SAFE OUTDOOR LOCATION UNTIL COOL.

Powering Down - Turning Off.

UNPLUG WHEN UNATTENDED.

A) Turn off all devices powered by the battery.

B) Unplug all devices and wiring from the battery.

|

| 1.1.2.1.6. VMAX Lithium Ion - A123 Nanophosphate - Charging | Charging correctly safely provides the best performance from your battery and maximizes it's life span.

VMAX Lithium Ion batteries use A123 Nanophosphate cells. These cells are considerably more tolerant of over discharge, over charge and current values than many other batteries. They are more robust and much safer than Lithium Polymer batteries. However, it is important to use common sense, follow instructions and understand what you are doing when charging.

A) From the battery label determine:

Voltage - Make sure you know the voltage of and the number of cells (Voltage/3.3) in the battery. Consult the battery label. Typical values for VMAX Lithium Ion batteries are as follows: 3.3V (1 cell), 6.6V (2 cells), 9.9V (3 cells), 13.2V (4 cells), 16.5V (5 cells) etc

Capacity - This is stated on the battery label in mAh for example 1100 mAh, 2300 mAh etc.

MAX CHARGE - A123 Nanophosphate Cells can be charged at up to the 5C rate. The actual 5C current value in Amps is stated on the battery. Make sure you do not exceed the MAX CHARGE current when charging.

Balance Voltage - A123 Nanophosphate cells perform best when balanced. The balancing voltage should not exceed 4.2V/cell. This is best done at a low current value such as 50mA or less. Although balancing is important it is less critical with A123 Nanophosphate cells than Lithium Polymer. Typically 95% of more of the battery capacity can be obtained without balancing. The final 5% of capacity requires balancing.

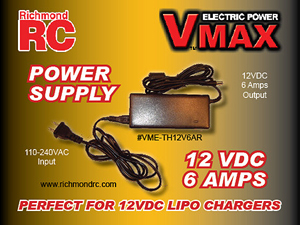

B) Select your charger. We recommend a charger that is capable of balancing the cells. Slow chargers will take up to a few hours to charge your battery and generally connect only via the white balance connector on your battery. Fast Chargers can charge your battery in a little as 15 minutes provided that the charger is capable of operating at the 5C charge rate. Fast chargers usually work with dual connections, one set of wires runs to the power connector on the battery while a second set runs to the balance connector.

The VMAX Slow Charger #VME-LPBC10 works well 2 and 3 cell VMAX Lithium Ion batteries. No programming or switch settings are required.

The VMAX Fast Charger #VME-LPBC50 works well with VMAX Lithium Ion batteries having up to 5 cells (16.5 Volts). This charger uses a menu driven program to set voltage and current limits.

C) Follow the instructions that came with your charger. Set your charger to match the Voltage, Capacity, Max Charge and Balance Voltage of your battery. In many cases the capacity is not selectable and the charger will automatically bring the battery to near 95% capacity before beginning a slower trickle charge cycle to top up the final 5% of capacity.

DO NOT CHARGE UNATTENDED

STAY ALERT FOR OVERHEATING, SMELLS, SMOKE OR OTHER SIGNS OF TROUBLE. UNPLUG ALL CONNECTIONS IMMEDIATELY IF THE BATTERY OR ANY CORD OR DEVICE OVERHEATS, SMELLS, SMOKES, SPARKS OR MAKES ANY UNEXPECTED NOISE OR EMISSION AND REMOVE COMPONENTS TO A SAFE OUTDOOR LOCATION UNTIL COOL.

D) When charging is complete, unplug your battery from all connections and unplug your charger and/or the power supply connected to your charger.

UNPLUG WHEN UNATTENDED

|

| 1.1.2.1.7. VMAX Lithium Ion - A123 Nanophosphate - No No's & Must Do's | Do NOT OPERATE NEAR FLAMMABLE MATERIALS. Do not operate near flammable liquids or gases, on or near a carpet or any flammable surface.

Do NOT OPERATE inside an automobile or other vehicle. If using a cigarette lighter adapter or connecting to automobile power ensure that the cord is long enough to connect to the battery located outside and away from the vehicle.

Do NOT OPERATE WHEN BATTERY IS HOT. Vmax Lithium Ion batteries use A123 Nanophosphate cells. These cells heat up much less under high current loads that Lithium Polymer batteries. Vmax Lithium Ion batteries will feel warm when providing high current but should not become so hot that you cannot tough them. If the becomes too hot to comfortably touch, understand why it is hot. Check your connections. If the battery and anything it is connected to appears to be functioning properly the battery may be overloaded by devices to which it is connected. Reduce the load.

Do NOT MODIFY WIRING OR CONNECTORS. If your battery was supplied with factory installed connectors we strongly suggest using these connectors. If a battery connector is not compatible with the device to which you intend on connecting the battery, use an adapter rather than changing connectors on the device or the battery.

CONNECT TO DEVICES HAVING COMPATIBLE VOLTAGE & CURRENT REQUIREMENTS. Ensure that the output voltage and current of your battery is compatible with the device you intend connecting it to. Ensure that external devices do not overload the battery with more current than it can supply.

DO NOT OPERATE in a WET ENVIRONMENT. This battery is NOT intended for operation in a wet environment. It is NOT water or weather proof. Keep the battery dry and clean at all times.

CHARGE CORRECTLY. Review the voltage, charging current limit and balancing voltage stated on the battery label. Review the charging guidelines provided elsewhere in this document. Review the instructions that came with your charger and ensure that you know how to connect to and control the output from your charger.

ALWAYS UNPLUG WHEN UNATTENDED. Do not leave your battery connected to anything when unattended. Nothing!

|

| 1.1.2.1.8. Support | On Line, eMail, Fax, Phone, Mail

|

| We offer the Best in Support Services. | We back up our products and our customers with the best support services available. From our industry leading Knowledge Base to information about your Shipment, we've got you covered!

To access our Support Services please:

Your Choice of Support Services that Work for You:

|

| 1.1.2.1.8.1. Contact Us | For Sales and other Inquiries

|

| Support - Contact Us - Reach our Sales Department by eMail, Fax, Phone or Mail | Technical Inquiries: Please review the information provided in our Knowledge Base. After checking our Knowledge Base, if you need further assistance please use our Submit A Question service to get a response within 2 Business Days. Sales Inquiries: Please note that our Sales Department personnel are trained and dedicated to:

- Helping you with non-technical pre-purchase questions,

- Helping you place your order,

- Pointing out any sales, combos or specials that you may wish to consider,

- Inputting your order to our computer system so that it ships out as accurately and quickly as possible... usually the same day,

- Resolving any invoicing problems, and

- Helping to sort out any missing shipment or shipment damage issues.

Their depth of technical knowledge is about on par with what is shown in our printed sales literature. In most cases, they are working from the same printed advertisements or content from our web site that you are. Asking sales personnel to confirm the size, color and availability of a product is well within their capabilities. However, asking detailed questions about technical issues is not.

Buy our Products:

For All Other Inquiries... please consult the following resources:

- On Line Information

- On Line Support Services

- After reviewing our On Line resources, if you require additional assistance please contact us by eMail, fax, phone or mail as follows:

- Ask a Question

- eMail

- Fax

- Phone

- Mail

- Richmond RC Supply Ltd, #114 - 7350 72nd Street, Delta, BC, V4G-1H9

- Mail & printed correspondence only.

- We are not able to accomodate personal site visits or drop-offs/pick-ups at this location.

- Please note that all inbound Shipments require pre-Authorization in advance.

- Unauthorized inbound shipments will be refused.

|

| 1.1.2.1.9. Warranty | |

This product is warrantied to the original buyer to be free of manufacturing defects for a period of 6 months from date of purchase.

Problems caused by alteration, normal wear and tear, physical damage, abuse, improper use, failure to comply with the setup and operating instructions, customer disassembly, changes to the wiring or connectors or damage caused by incorrect charging or damage caused by the use of other accessories or products to which the battery was connected are not covered by this warranty.

All warranty returns MUST be accompanied by an RMA number and a dated sales receipt from an authorized VMAX re-seller and the original VMAX packaging along with all of the adapters and connectors supplied with this product.

All returns must be SHIPPED PREPAID to the VMAX Service Center in your market area.

See "Support" for information about Warranty Claims.

|

| 1.1.2.1.10. Keep Up to Date | Check Frequently for Updates |

| Support - Stay Current - Check Frequently for Updated &/or Additional Information | This information is subject to change without notice. When viewing this information in a printed form the printing date will be visible in the lower right corner. Check frequently for updates &/or Additional Information.at www.richmondrc.com, > Enter the Site, > Support Services, follow the links to our Knowledge Base. Review the Table of Contents and search for the name and/or part number of this product.

For automated notification of changes to information contained in our Knowledge Base please register as a Priority Response member and subscribe to our Priority Response Notification Service.

|

| 1.1.2.2. VMAX Lithium Ion - A123 Nanophosphate - Additional Information | In general "Additional" Information is:

- In addition to that found in other documentation related to this product,

- Often reflects feedback &/or questions from users of the product.

Subject to the Conditions of Use, please review the attachments and related articles listed below.

|

| 1.1.2.3. VMAX Lithium Ion - A123 Nanophosphate - Pictures, Graphics & Artwork |

| 1.1.2.3.1. Pictures - VMAX Lithium Ion - A123 Nanophosphate |

| 1.1.2.3.1.1. Pictures (CMYK_TIF) VMAX Lithium Ion - A123 Nanophosphate |

| 1.2.1. VME-LPBC10 & VME-LPBC10S VMAX Battery Charger for 2-3 Cell LiPO Battery Packs | Please note that #VME-LPBC10 is the VMAX Battery Charger itself with the DC input cord (with alligator clips). In some markets the #VME-LPBC10 VMAX Battery Charger is sold only in this format.

#VME-LPBC10S is the VMAX Battery Charger "S"et and consists of the VMAX Battery Charger (#VME-LPBC10) plus "XH" style output adapters to connect with 2 and 3 cell LIPO packs having 5 slot balance connectors (very common) and the READ ME FIRST Operations Manual in a bundle complete with display packaging.

Users of #VME-LPBC10 VMAX Battery Charger may benefit from some of the additional information found in the READ ME FIRST Operations Manual bundled with #VME-LPBC10S VMAX Battery Charger Set.

|

| 1.2.1.1. VME-LPBC10S VMAX Battery Charger for 2-3 Cell LiPO Battery Packs - READ ME FIRST Operations Manual | The READ ME FIRST Operations Manual is available here as a pdf: |

| 1.2.1.2. VME-LPBC10 & VME-LPBC10S VMAX Battery Charger for 2-3 Cell LiPO Battery Packs - Pictures, Graphics & Artwork |

| 1.2.1.2.1. Pictures VME-LPBC10 VMAX for 2-3 Cell LiPO Battery Packs |

| 1.2.1.2.1.1. Pictures (CMYK_TIF) VME-LPBC10 VMAX for 2-3 Cell LiPO Battery Packs |

| 1.3. Motors - Brushless - Electric |

| 1.3.1. VMM-111B18VM VMAX 11.1 Volt Motor - Brushless - 15A 130W Max |

| 1.3.1.1. Mounting Screws - What to use on VMM-111B18VM VMAX Brushless Motor | Question: I have a VMAX #VMM-111B18VM VMAX Brushless Motor. What do I need in the way of mounting screws?

Answer: There are a several options for this depending on what you have in mind:

a) VMAX VMAX #VMM-111B18VM VMAX Brushless Motors that are supplied with VMAX Power Modules and VMAX Power Packs come pre-mounted with the appropriate screws for the motor.

b) The threads are 3mm and generally four 3mm x 6-12 mm machine hex head screws with washers will work.

c) We sell a Mounting Screw Set (#VMM-111B18MS) consisting of four 3mm x 10mm hex head screws. Hex head screws should be used with flat washers under the heads.

d) We also sell a Mounting Screw Set (#VMM-111B18MT) consisting of 16 mounting screws. Four screws in each of four different sizes/styles.

- 3 x 10 mm Hex head machine screws (4) (like VMM-111B18MS)

- 3 x 16 mm Hex head machine screws (4) (longer version of above)

- 3 x 6 mm Phillips countersink head screws (4) (for flush fitting)

- 3 x 10 mm Phillips countersink head screws (4) (for flush fitting)

The four different sizes/styles allow for thicker firewalls, multi-layer firewalls where the screw heads must be countersunk between the layers, etc.

This set provides for a very wide range of different mounting methods.

Hex head screws should be used with flat washers under the heads.

CAUTION: When mounting motors using any method, ensure all fasteners are tightened securely. Check for vibration free operation of the motor. If not vibration free, reseat and retighten all fasteners and ancilliary components such as props and gears. Tighten fasteners firmly but don't strip the threads. Use medium strength thread locker on all metal to metal fasteners.

|

| 1.3.1.2. Propeller Adapter - What to use on VMM-111B18VM VMAX Brushless Motor | Question: I have a VMAX #VMM-111B18VM VMAX Brushless Motor. What prop adapter works on this motor?

Answer: There are a several options for this depending on the prop that you are using.

Please note that the motor comes with a long threaded shaft that is .118 in. (3 mm) in diameter. We sell a prop nuts and washer set (#VMM-111B18PN) that contains an assortment of nuts, safety nuts and washers suitable for mounting most suitable props on this shaft. Please note that if you bought a VMAR Power Module or Power Pack for your model the appropriate nuts, safety nuts and washers and prop are already included. Method A, B and C described below utilize the prop nuts and washer set #VMM-111B18PN.

Method A: This is applicable to the older version of Master Airscrew #MAS-0850NE prop that has a recessed hex shaped hole in the back of the prop. No collets come with this older version of the 0850NE prop to adapt the prop to fit different shaft sizes.

For installation of this older style of #MAS-0850NE prop, we recommend the following order of components working from the motor out towards the tip of the shaft : Motor > Nut > Washer > Nut > Nut > Prop > Washer > Safety Nut. The idea here is that the pair of two hex nuts (Nut > Nut) insert themselves into the recess in the back of the prop.

Method B: This is similar to Method A but uses a Safety Nut instead of the pair of two hex nuts. Working from the motor out towards the tip of the shaft install the following components: Motor > Nut > Washer > Safety Nut (hex end towards prop) > Prop > Washer > Safety Nut. The idea here is that the hex end of the first Safety Nut inserts itself into the recess in the back of the prop.

Method C: This is applicable to the newer version of Master Airscrew #MAS-0850NE prop that has a recessed hole in the back of the prop that works with a collet suitable for the motor shaft size. A selection of collets with different internal hole diameters is provided with the prop. Working from the motor out towards the tip of the shaft install the following components:

Motor > Nut > Washer > Collett and Prop > Washer > Safety Nut. The idea here is that the Collett and Prop are cinched between the two washers.

Method D: Use a conventional squish type 3 or 4 segment prop adapter suitable for the motor shaft size referenced above.

To use such an adapter measure the motor shaft length that you require for your application (i.e. it must fit in your model and clear the front of the model and/or cowl) and then cut off the excess shaft length. In general you use the fasteners that come with the segmented prop adapter.

CAUTION: When mounting props using any method, ensure all hardware and fasteners are tightened securely. Check for wobble free rotation of the prop and motor. If not wobble free, loosen the prop, reseat it and tighten securely. Tighten the nuts firmly but don't strip the threads.

|

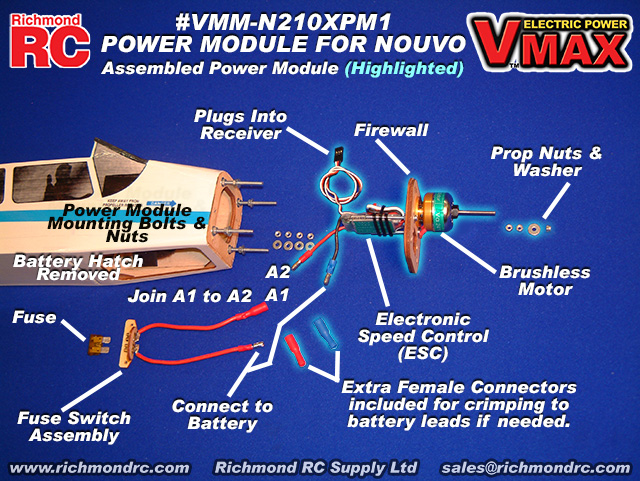

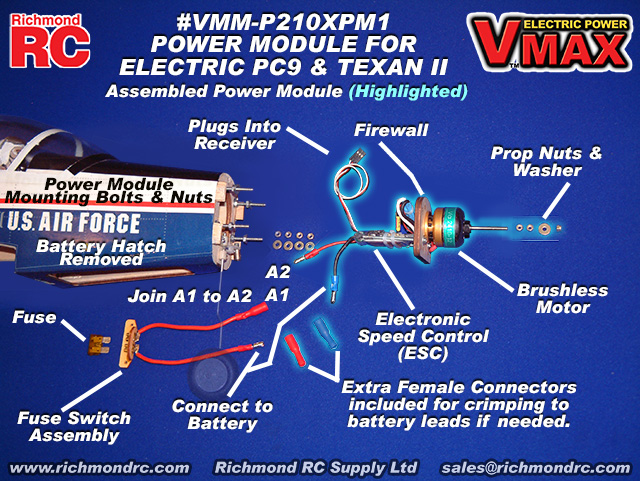

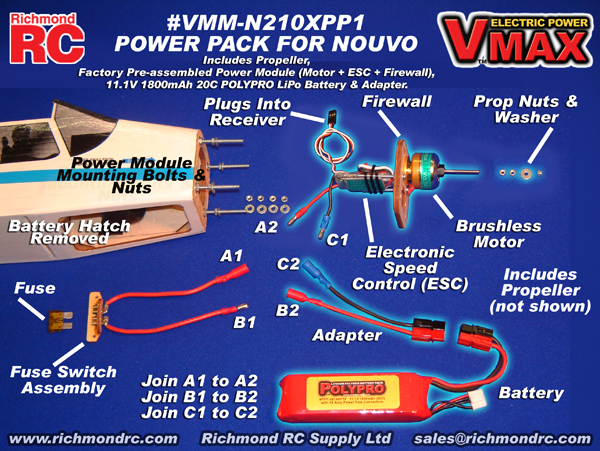

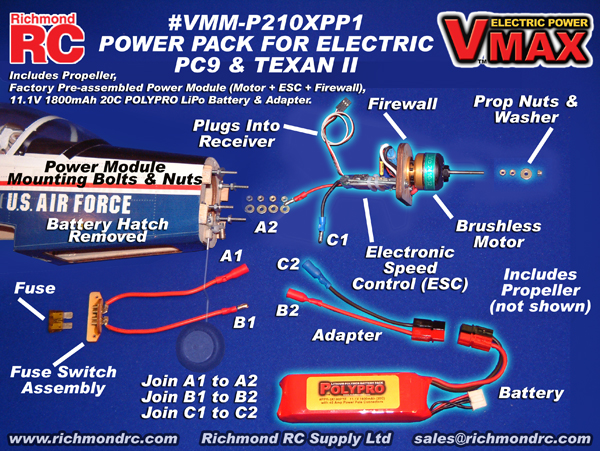

| 1.4. Power Module Set (Electric) - Brushless Motor, ESC & Firewall | VMAR Power Module Sets for VMAR Electric ARF models contain the motor and speed control components related to the electric power (propulsion) system and can be easily mounted on the customized Power Module Firewall engineered to fit the particular model and supplied with the model. |

| 1.4.1. Power Module Set - For VMAR Electric Models - Overview | VMAR Power Module Sets are intended for modelers who already have their own Li Po Battery, Servos, Props and wiring systems but who wish to purchase an easy to install power system including the firewall(s), motor(s) and speed control(s) that have been factory designed for and tested with their VMAR model.

|

| 1.4.2. Power Module Set - For VMAR Electric Models - Typical Contents |

VMAR Power Module Sets are factory designed for each VMAR Electric Model and contain the firewall(s), electric motor(s) and electronic speed controls(s) (ESC) for the applicable model. A VMAX Power Module Set typically consists of the following components: - Laser cut wood power module firewall.

- This may also be supplied with the model (in a parts bag)

- Brushless Motor (#VMM-111B18VM)

- With four (4) 3mm socket head bolts and 4 flat washers fitted for shipping.

- Propellor Mounting Hardware.

- One (1) 3mm security lock nut is fitted on the threaded motor shaft for shipping.

- Three (3) 3mm nuts and two (2) #6 flat washers are supplied in a parts bag.

- Electronic Speed Control ("ESC") (#VMC-120B15VC).

- Red, White & Black three (3) wire lead set attached to ESC for connection to Brushless Motor.

- Red (+), Black (-) two (2) wire lead set attached to ESC for DC power input.

- Two (1 Red, 1 Blue) crimp on female bullet connectors for power battery leads.

- RC servo plug on Red, White, Black three (3) wire set for connection to RC receiver throttle channel.

- Four zip straps.

- READ ME FIRST documentation.

Power Module Sets for Multi-Motor Models: - Power Module Sets for multi-motor models will contain multiple firewalls, motors and speed controls as required to power the model.

- For each ESC in the Power Module Set we also include 1 Red and 1 Blue female crimp on bullet connector for use with user supplied power leads.

- For each motor in the Power Module Set we also include propeller mounting hardware.

VMAR Power Module Sets do NOT include:

- Wiring or connectors other than the leads attached to motor and attached to the electronic speed control and the red and black female bullet connectors noted above.

- Propeller

- Li Po Battery Pack

- Servos

These components are NOT included in the Power Module Set and will be needed to complete your model. If you do not already have these items, they will need to be obtained separately.

|

| 1.4.3. Power Module Set - For VMAR Electric Models - Propeller Mounting |

VMAR Power Module Sets come with propeller mounting hardware that works with the propeller we recommend AND can be adapted to work with most other propellers.

a) We include the following: Three (3) 3 mm plain nuts, One (1) 3 mm security nut with fiber insert, Two (2) flat washers.

b) For propellers without a collet set and having a round hole in the back of the propeller hub that is bigger than the motor shaft or having a 3mm hexagonal recess in the back of the propeller hub: First thread one of the 3 mm plain nuts onto the shaft and position it about 3/4 in. (19 mm) from the open end of the shaft. Then install one flat washer followed by two of the 3 mm plain nuts (tighten snugly), then the prop, then a second flat washer and finally one of the 3 mm security nuts. Push the propeller towards the motor so that the two plain nuts are inserted into the recess in the back of the propeller hub and the back of the hub is against the adjacent flat washer. Tighten the 3 mm security nut so that the second flat washer is firmly in contact with the front of the propeller hub. In summary, the components are arranged as follows: Motor > 3 mm nut > flat washer > two (2) 3 mm nuts > propeller > flat washer > security nut.

c) For propellers with a collet set and having a larger recessed round hole in the back or front of the propeller hub that will accomodate a collet: Select a collet that has a center hole 3 mm (approx 1/8 in.) in diameter. Insert the collet into the hole in the propeller hub. From this point on treat the propeller and collet as one unit i.e. the "propeller". Next thread one of the 3 mm plain nuts onto the shaft and position it about 3/4 in. (19 mm) from the open end of the shaft. Then install one flat washer then the prop, then a second flat washer and finally one of the 3 mm security nuts. Push the propeller towards the motor so that the back of the propeller hub is against the adjacent flat washer. Tighten the 3 mm security nut so that the second flat washer is firmly in contact with the front of the propeller hub. In summary, the components are arranged as follows: Motor > 3 mm nut > flat washer > propeller > flat washer > security nut.

d) For propellers having a 3 mm (approx 1/8 in.) round hole that runs completely through the propeller hub with no other hole or recess in the back or front of the hub: Thread one of the 3 mm plain nuts onto the shaft and position it about 3/4 in. (19 mm) from the open end of the shaft. Then install one flat washer, then the prop, then a second flat washer and finally one of the 3mm security nuts. Push the propeller towards the motor so that the back of the hub is against the adjacent flat washer. Tighten the 3mm security nut so that the second flat washer is firmly in contact with the front of the propeller hub. In summary, the components are arranged as follows: Motor > 3mm nut > flat washer > propeller > flat washer > security nut.

e) For other propellers: We suggest obtaining a "squish" or "cinch" type propeller adapter suitable for 3mm shafts. You may wish to cut the motor shaft to a shorter length. Measure and test carefully before shortening the motor shaft with due consideration for any cowl and/or propeller clearance.

|

| 1.4.4. Power Module Set - For VMA-B210X Bird Dog - Brushless Motor, ESC & Firewall | 20200428... Please review the information included below. |

| Power Module Set - For VMAR Electric Models - Typical Contents |

VMAR Power Module Sets are factory designed for each VMAR Electric Model and contain the firewall(s), electric motor(s) and electronic speed controls(s) (ESC) for the applicable model. A VMAX Power Module Set typically consists of the following components: - Laser cut wood power module firewall.

- This may also be supplied with the model (in a parts bag)

- Brushless Motor (#VMM-111B18VM)

- With four (4) 3mm socket head bolts and 4 flat washers fitted for shipping.

- Propellor Mounting Hardware.

- One (1) 3mm security lock nut is fitted on the threaded motor shaft for shipping.

- Three (3) 3mm nuts and two (2) #6 flat washers are supplied in a parts bag.

- Electronic Speed Control ("ESC") (#VMC-120B15VC).

- Red, White & Black three (3) wire lead set attached to ESC for connection to Brushless Motor.

- Red (+), Black (-) two (2) wire lead set attached to ESC for DC power input.

- Two (1 Red, 1 Blue) crimp on female bullet connectors for power battery leads.

- RC servo plug on Red, White, Black three (3) wire set for connection to RC receiver throttle channel.

- Four zip straps.

- READ ME FIRST documentation.

Power Module Sets for Multi-Motor Models: - Power Module Sets for multi-motor models will contain multiple firewalls, motors and speed controls as required to power the model.

- For each ESC in the Power Module Set we also include 1 Red and 1 Blue female crimp on bullet connector for use with user supplied power leads.

- For each motor in the Power Module Set we also include propeller mounting hardware.

VMAR Power Module Sets do NOT include:

- Wiring or connectors other than the leads attached to motor and attached to the electronic speed control and the red and black female bullet connectors noted above.

- Propeller

- Li Po Battery Pack

- Servos

These components are NOT included in the Power Module Set and will be needed to complete your model. If you do not already have these items, they will need to be obtained separately.

|

| More Information about Power Modules | Links to More Information:

|

| 1.4.5. Power Module - For VMA-C210X Cub & L4 - Brushless Motor, ESC & Firewall | This Power Module (VMM-C210XPM1) includes the components listed below. - (The laser cut wood power firewall is part #VMA-C210XPMV.)

|

| Power Module Set - For VMAR Electric Models - Typical Contents |

VMAR Power Module Sets are factory designed for each VMAR Electric Model and contain the firewall(s), electric motor(s) and electronic speed controls(s) (ESC) for the applicable model. A VMAX Power Module Set typically consists of the following components: - Laser cut wood power module firewall.

- This may also be supplied with the model (in a parts bag)

- Brushless Motor (#VMM-111B18VM)

- With four (4) 3mm socket head bolts and 4 flat washers fitted for shipping.

- Propellor Mounting Hardware.

- One (1) 3mm security lock nut is fitted on the threaded motor shaft for shipping.

- Three (3) 3mm nuts and two (2) #6 flat washers are supplied in a parts bag.

- Electronic Speed Control ("ESC") (#VMC-120B15VC).

- Red, White & Black three (3) wire lead set attached to ESC for connection to Brushless Motor.

- Red (+), Black (-) two (2) wire lead set attached to ESC for DC power input.

- Two (1 Red, 1 Blue) crimp on female bullet connectors for power battery leads.

- RC servo plug on Red, White, Black three (3) wire set for connection to RC receiver throttle channel.

- Four zip straps.

- READ ME FIRST documentation.

Power Module Sets for Multi-Motor Models: - Power Module Sets for multi-motor models will contain multiple firewalls, motors and speed controls as required to power the model.

- For each ESC in the Power Module Set we also include 1 Red and 1 Blue female crimp on bullet connector for use with user supplied power leads.

- For each motor in the Power Module Set we also include propeller mounting hardware.

VMAR Power Module Sets do NOT include:

- Wiring or connectors other than the leads attached to motor and attached to the electronic speed control and the red and black female bullet connectors noted above.

- Propeller

- Li Po Battery Pack

- Servos

These components are NOT included in the Power Module Set and will be needed to complete your model. If you do not already have these items, they will need to be obtained separately.

|

| More Information about Power Modules | Links to More Information:

|

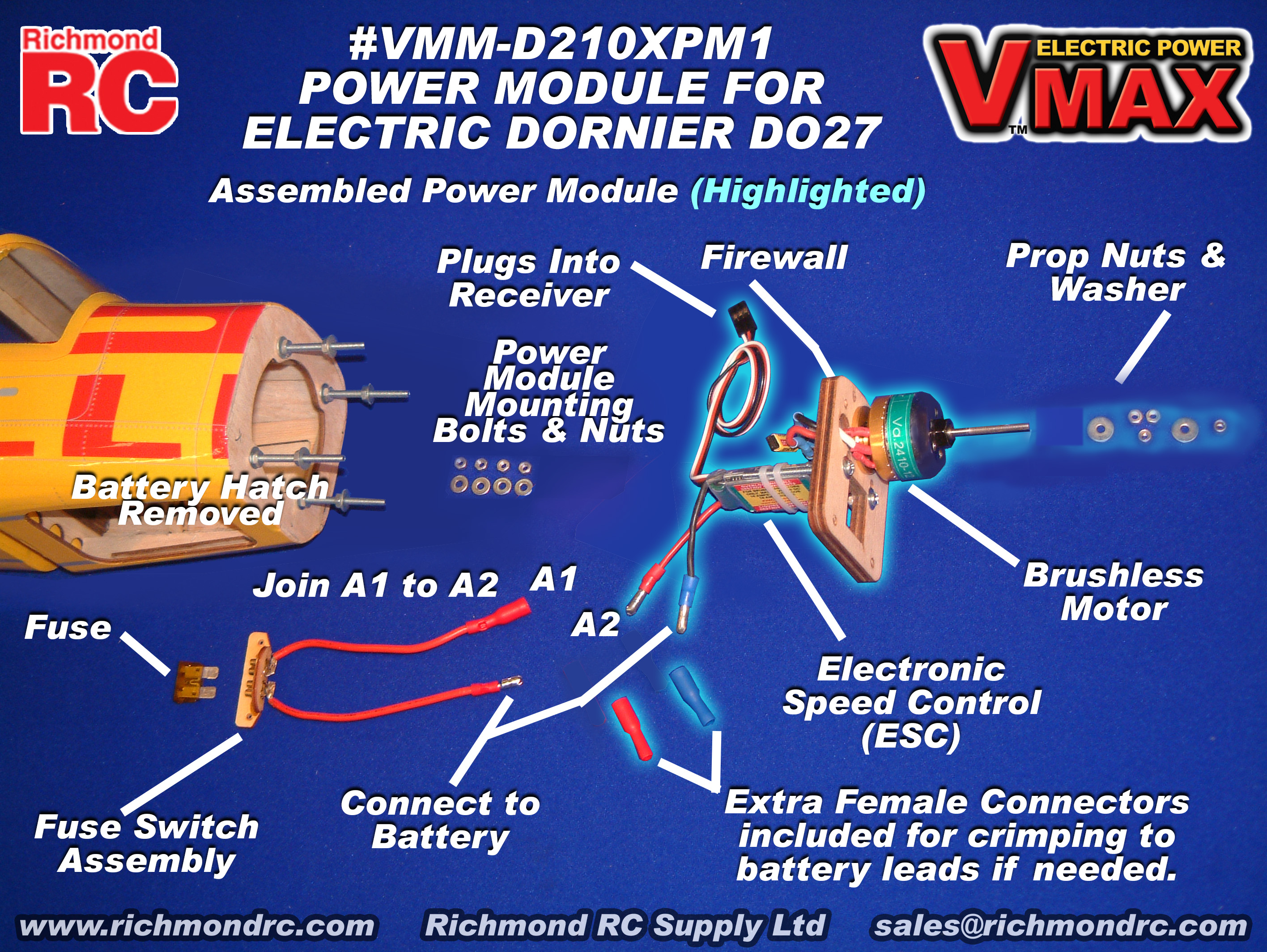

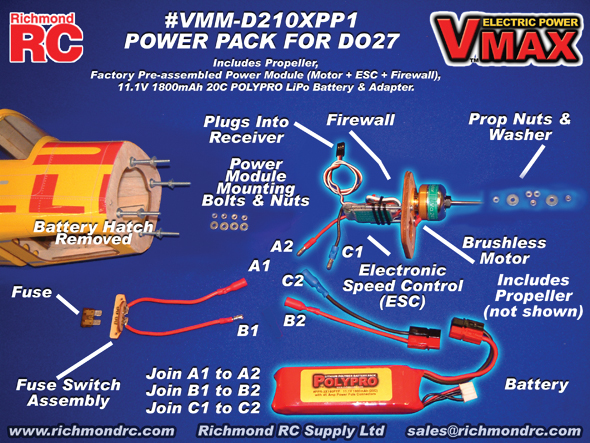

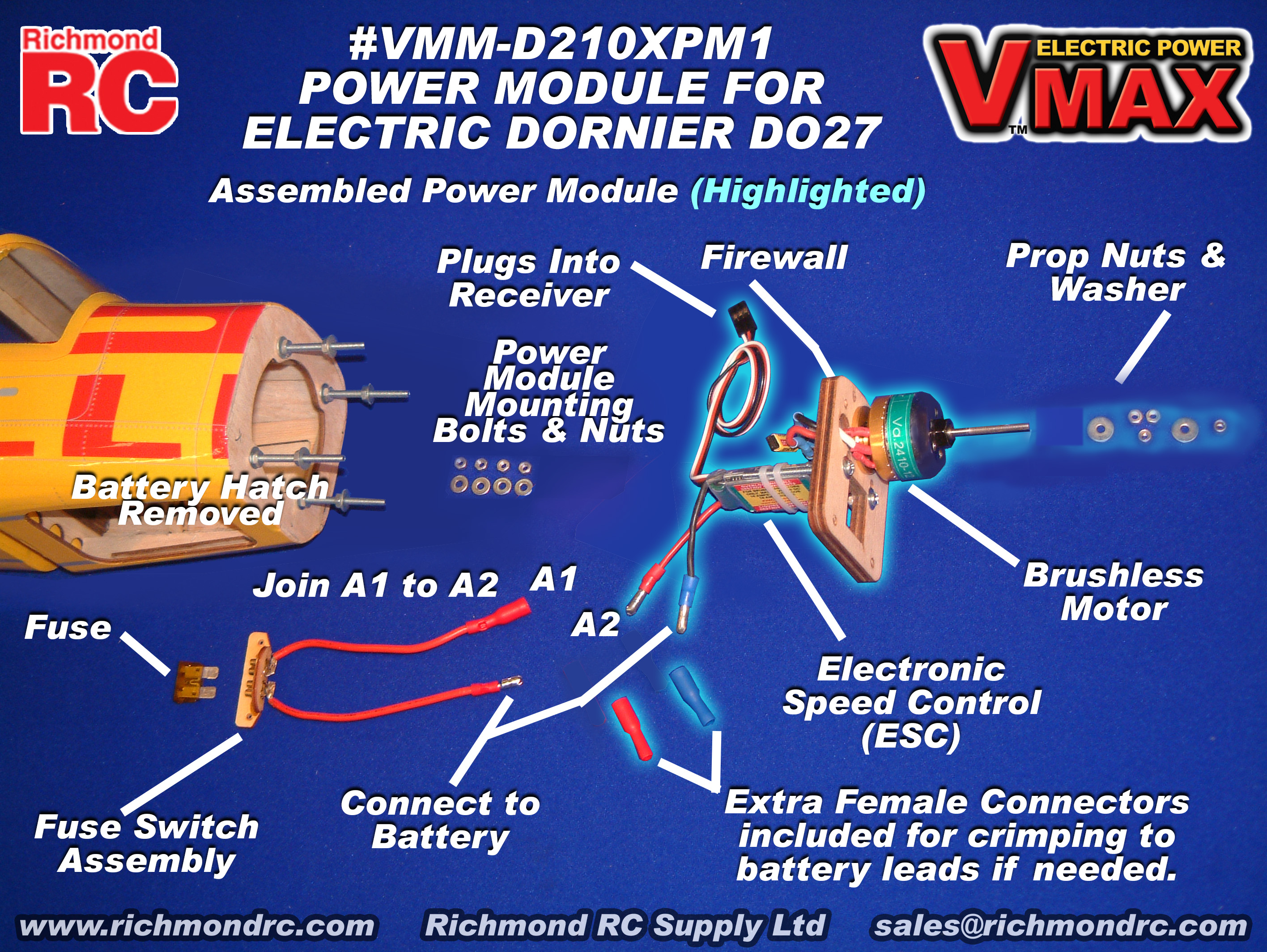

| 1.4.6. Power Module Set - For VMA-D210X DO27 - Brushless Motor, ESC & Firewall | VMM-D210XPM1 POWER MODULE SET |

| 1.4.6.1. Power Module Set - #VMM-D210XPM1 For VMA-D210X DO27 - READ ME FIRST | PLEASE READ ME FIRST

BEFORE PROCEEDING TO ASSEMBLE OR OPERATE THIS PRODUCT |

| LIABILITY DISCLAIMER & COPYRIGHT NOTICE | LIABILITY DISCLAIMER

The authors and/or suppliers and/or disseminaters of this information and/or product expressly disclaim any warranties or representations, either expressed or implied, including but not limited to implied warranties of fitness, accuracy, timeliness or applicability of the information and/or product provided here. In no event will the authors and/or suppliers and/or disseminaters of this information and/or product have any obligation arising from contract or tort, for loss of revenue or profit, or for indirect, special, incidental, consequential or other damages of any sort arising from this information and/or product. In using this information and/or product, the user accepts all responsibility for and all liability associated with such use.

PROCEEDING WITH THE USE OF THIS INFORMATION AND/OR PRODUCT INDICATES AGREEMENT WITH AND ACCEPTANCE OF THE LIABILITY DISCLAIMER.

|

| Please Note the following Caution | CAUTION

A Remote Control (RC) model aircraft is not a toy. It is a flying model that functions much like a full size airplane. If you do not assemble and operate model aircraft properly you can cause injury to yourself and others and damage property. DO NOT FLY a model aircraft unless you are qualified.

You are ultimately responsible for the mechanical, aeronautical and electrical integrity of any model you fly and all of the components that make up the model including but not limited to the airframe itself, control surfaces, hinges, linkages, covering, engine, motor, radio, servos, switches, wiring, battery and parts. Check all components before and after each flight. It is essential that you act with the clear understanding that you are solely responsible for all aspects of the model at all times. DO NOT FLY until it is right.

|

| When working with Batteries, Electric Models, Motors & Propellers, Chargers & Electrical Devices |

|

ALWAYS DISCONNECT THE BATTERY

or other electrical power source from any motor, device or charger when transporting, storing, not using or when you are not in attendance.

Keep hands, tools, clothing and all foreign objects well clear of equipment prior to and during operations. Take particular care to safeguard and protect your eyes and fingers and the eyes and fingers of other persons who may be nearby.

STAY CLEAR OF PROPELLER. PROTECT YOURSELF & OTHERS AT ALL TIMES

Use only a good quality propeller that has no cracks or flaws. Ensure propellers are securely attached. Stay clear of the propeller and stay clear of the plane of rotation defined by the propeller prior to connecting your battery to any motor or power system.

|

|

| 1.4.6.1.2. Power Module Set - For VMA-D210X DO27 - General Information | |

| COPYRIGHT | Copyright Richmond RC Supply Ltd. All rights reserved.

|

| Tips for Avoiding Common Problems |

We have supplied thousands and thousands and thousands of model aircraft in the past 20 plus years. We're not bragging! We tell you this to give some credibility to our suggested list of tips that follow. In talking to modelers around the world, here is what we have found is the key to...

AVOIDING 90% of PROBLEMS that can arise:

- READ THE CAUTION ABOVE & READ THE LIABILITY DISCLAIMER.You are responsible for all aspects of any model you fly. You're It!

- READ ALL DOCUMENTATION before doing anything else!

- INSPECT CAREFULLY immediately upon arrival!.

- RETAIN ALL PACKAGING until the checkout is complete! If you need to return anything you must have all of the original packaging.

- READ & LOOK! At everything! Do it once & then do it again.

- REMEMBER WHAT "ARF" STANDS FOR. ARF means ALMOST Ready to Fly with an emphasis on ALMOST! Some assembly and modeling skills are required.

- ALLOW ENOUGH TIME to enjoy the assembly process! Rushing into a 6 hour job with 3 hours to spare simply will not work. This is a Hobby... take your time.

- DRY FIT & TEST ASSEMBLE EVERYTHING before you glue anything!

- USE 30 MINUTE EPOXY when joining wings & installing stabilizers and other structural components but only after you have dry fitted and test assembled the components without glue! Once parts are glued together they cannot be unglued and they cannot be returned or replaced without charge.

- PLAN AHEAD! BE CAREFUL! If you get into trouble, DON'T PANIC. Review everything again, talk it over with an experienced modeler and if still in difficulty consult our Support Services.

- TEST TEST!!! TUG TUG TUG!!! EVERYTHING... BEFORE & AFTER EACH FLIGHT! Your model may have been largely pre-constructed and may have pre-installed control rods, hinges, control surfaces and many other essential components. Hinges may have been pinned after they have been installed. However, you must double check every control surface and component before and after each flight. You and only you are responsible for the integrity of all components and the integrity of the model itself. Check everything before and after each flight. Tug on control surfaces, control rods, mounting bolts, T-nuts, mounting plates... tug on everything!

- DO NOT OVER TIGHTEN WING BOLTS or other fasteners. You want bolts and nuts snugly tight and if metal you can use a medium grade thread locker such as Pacer Z42 to help them stay tight. Fasteners must be snug and secure. However a model airplane is not a farm tractor or a garbage compactor. You do not need a pipe wrench or an electric drill to tighten up wing bolts or any other fastener. Leave your plumbing and power tools at home.. hand tools only and go easy on the torque... snug and secure... not stripped or torqued until they squeak or break. Wing bolts can take tremendous torque before breaking... but when you over tighten them or use an electric screw driver on a set of wing bolts, long before the bolts break you can fracture the fuselage, crack the mounting blocks or pull the heads of the bolts through the wing... these problems have a nasty habit of revealing themselves when you least expect the wing to fall off!

- DO NOT OVERPOWER ANY MODEL! Stay within the recommended power range for the model. If you overpower the model you run a high risk of structural failure that will lead to loss of control and a subsequent crash that will destroy the model and may cause injury and/or property damage.

- ASSUME NOTHING! Remember the old yarn about what happens when you ASS-U-ME something. Check everything repeatedly and frequently and DO NOT FLY any model unless you are satisfied that everything is in good working order.

|

| 1.4.6.1.3. Power Module Set - For VMA-D210X DO27 - Introduction | |

Before beginning the Installation Instructions please read the Overview and check off the components provided. Each component is in a labelled parts bag. Please check off the components against the Contents list below. Leave the components in their parts bags for now. Do not remove the components from their parts bags until each is needed during the installation process.

|

| Power Module Set - For VMAR Electric Models - Overview | VMAR Power Module Sets are intended for modelers who already have their own Li Po Battery, Servos, Props and wiring systems but who wish to purchase an easy to install power system including the firewall(s), motor(s) and speed control(s) that have been factory designed for and tested with their VMAR model.

|

| 1.4.6.1.4. Power Module Set - For VMA-D210X DO27 - Contents | This Power Module Set (#VMM-D210PM1) includes the components listed below.

- (The laser cut wood firewall is part #VMA-D210XPMV)

|

| Power Module Set - For VMAR Electric Models - Typical Contents |

VMAR Power Module Sets are factory designed for each VMAR Electric Model and contain the firewall(s), electric motor(s) and electronic speed controls(s) (ESC) for the applicable model. A VMAX Power Module Set typically consists of the following components: - Laser cut wood power module firewall.

- This may also be supplied with the model (in a parts bag)

- Brushless Motor (#VMM-111B18VM)

- With four (4) 3mm socket head bolts and 4 flat washers fitted for shipping.

- Propellor Mounting Hardware.

- One (1) 3mm security lock nut is fitted on the threaded motor shaft for shipping.

- Three (3) 3mm nuts and two (2) #6 flat washers are supplied in a parts bag.

- Electronic Speed Control ("ESC") (#VMC-120B15VC).

- Red, White & Black three (3) wire lead set attached to ESC for connection to Brushless Motor.

- Red (+), Black (-) two (2) wire lead set attached to ESC for DC power input.

- Two (1 Red, 1 Blue) crimp on female bullet connectors for power battery leads.

- RC servo plug on Red, White, Black three (3) wire set for connection to RC receiver throttle channel.

- Four zip straps.

- READ ME FIRST documentation.

Power Module Sets for Multi-Motor Models: - Power Module Sets for multi-motor models will contain multiple firewalls, motors and speed controls as required to power the model.

- For each ESC in the Power Module Set we also include 1 Red and 1 Blue female crimp on bullet connector for use with user supplied power leads.

- For each motor in the Power Module Set we also include propeller mounting hardware.

VMAR Power Module Sets do NOT include:

- Wiring or connectors other than the leads attached to motor and attached to the electronic speed control and the red and black female bullet connectors noted above.

- Propeller

- Li Po Battery Pack

- Servos

These components are NOT included in the Power Module Set and will be needed to complete your model. If you do not already have these items, they will need to be obtained separately.

|

| 1.4.6.1.5. Power Module Set - For VMA-D210X DO27 - Installation Instructions | |

Consult any labels carefully, particularly the larger WARNING labels. The labels are largely self explanatory. Reading the labels will save you a great deal of time and help prevent damage to your equipment.

|

| 1.4.6.1.5.1. Power Module Set for VMA-D210X DO27 - Installation Procedure |

a) Review the Read Me First documentation and the Assembly & Operations Manual that came with your model. b) In the Operations Manual please turn to Page 7, Stage 11. c) Review (but do not action) all Steps 11A through 11L inclusive. d) Review Figure 11F showing the wiring between the motor and the electronic speed control ("ESC"). Make sure you plug the wires together as follows:

Motor Red Wire to ESC Red Wire

Motor Black Wire to ESC WHITE Wire

Motor WHITE Wire to ESC Black Wire

If you do not connect the wires between the motor and the ESC as described above you can damage the motor &/or ESC or the motor may turn backwards. e) Review the supplementary information provided below regarding step 11K f) After reviewing the steps and the wiring of figure 11F and the supplementary information provided below, proceed carefully with steps 11A through 11L to assemble your power module.

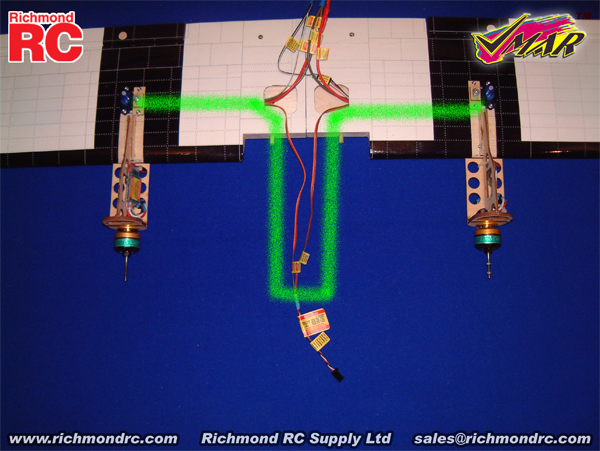

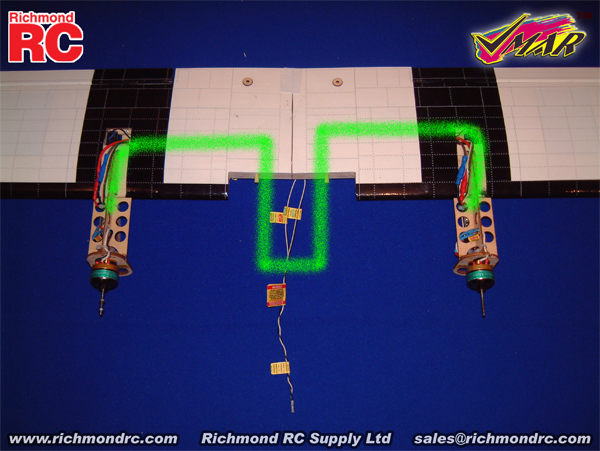

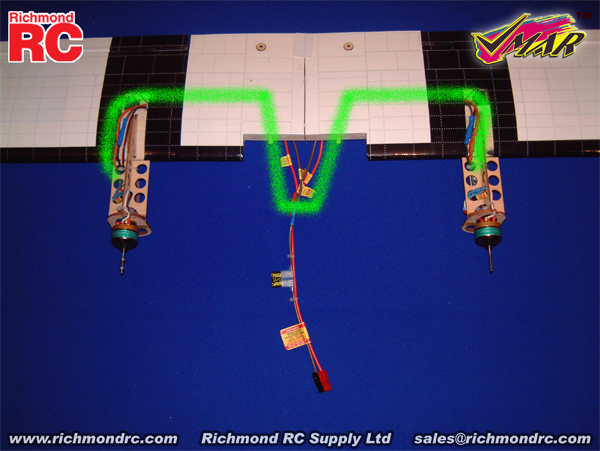

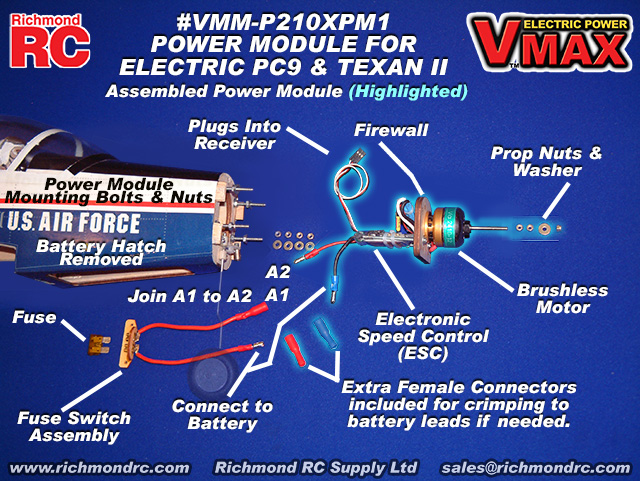

The following depiction illustrates the Fuselage and the assembled Power Module and how it is wired to the Fuse Assembly and Battery Pack:

|

| 1.4.6.1.6. Power Module Set - For VMA-D210X DO27 - Operating | |

Consult any labels carefully, particularly the larger WARNING labels. The labels are largely self explanatory. Paying attention to the operating limits will help prevent damage to your equipment.

We developed this Power Module as a "system" suitable for your model. We strongly advise against changing any component within this system. If a component requires replacement, ensure you replace it with a new but identical component to that which is being swapped out.

|

| 1.4.6.1.6.1. Propellers - Power Module Operations - VMA-D210X DO27 |

a) See the Warning label on the firewall. Do NOT exceed the maximum propeller size noted.

b) With power disconnected, double check the propeller to make sure it is not damaged or nicked in any way and that it is securely and safely mounted. Check before and after each flight.

c) Ensure the propeller turns true (no wobble) and that it is balanced and that all propeller fasteners are tight.

USING THE WRONG PROPELLER &/or OPERATING WITH EXCESSIVE VIBRATION WILL DESTROY THE MOTOR.

d) Ensure that your propeller is rotating clockwise when viewed from behind (looking forward as if you were in the cockpit) and that the prop is blowing air from the front of the model to the back.

f) If the propeller is rotating clockwise when viewed from behind but air is flowing from the back to the front of the model, the propeller is mounted on the motor backwards. Check and reinstall the propeller correctly. In general the brand logo and other writing on propellers should face forwards.

g) If the propeller is rotating backwards, reverse the black and white wire connections between the motor and the electronic speed control.

|

| 1.4.6.1.6.2. On the Ground - Power Module Operations - For VMA-D210X DO27 | Operating the brushless motor on the ground or in a static mode whereby the aircraft cannot move, puts peak loads on the motor while not providing adequate cooling normally generated in flight. Peak loads coupled with inadequate air flow leads to very rapid heat buildup within the brushless motor that can damage or destroy the motor very quickly.

ENSURE ADEQUATE COOLING. DO NOT OPERATE AT HIGH THROTTLE ON THE GROUND FOR LONGER THAN 10 SECONDS.

|

| 1.4.6.1.6.3. Powering Up - Power Module Operations - VMA-D210X DO27 |

a) Move your throttle stick all the way down to 0 (no power).

b) Turn on your transmitter

c) Turn on your receiver.

d) Ensure the model is held securely in order to test the motor system. Tie it down or hold the fuselage at the back.

STAY WELL CLEAR OF THE PROPELLER AND PLUG IN YOUR BATTERY.

e) Advance the throttle on your transmitter

f) The Electronic Speed Control (ESC) will apply power to the motor and the prop will begin to rotate. Very briefly advance the power to full throttle to ensure the motor spools up to full power. Do this for no more than 2-3 seconds at a time.

g) If the ESC beeps rather than makes the motor turn it is because the ESC is being powered up with the throttle stick at a non-zero position. This is a safety feature to prevent rotation of the prop unless you begin from a zero throttle position after each power up.

|

| 1.4.6.1.6.4. Motor Power Auto-Cutoff - Power Module Operations - VMA-D210X DO27 | The Electronic Speed Control (ESC) has an embedded "auto-cutoff" controller that will reduce battery power supplied to the motor as the battery reserve begins to run out. This auto-cutoff controller ensures that the battery retains sufficient energy to power the receiver and servos. As the energy reserve in the battery approaches "empty", the auto-cutoff begin to reduce power available for the motor while allocating the remaining energy to provide power for the receiver and servos so that you can maintain flight control using the remaining energy.

Land immediately when you detect that the motor power is beginning to fade. Once the power begins to fade, you have a very short time remaining before the ESC will auto-cutoff power to the motor.

|

| 1.4.6.1.7. Power Module Set - For VMA-D210X DO27 - No No's & Must Do's |

| Motors - No No's - That can Destroy Your Motor | Question: Are there any No No's that I should be careful to stay clear of when running my Brushless Motor?

Answer: We have sold many many brushless motors. From the questions and service requests we get we can pretty well sum up the No No's and Must Do's as follows:

a) Read Everything First! Every instruction! Every Warning Label! Browse our Knowledge Base while you are at it. About 90% of problems can be avoided by Reading First.

b) Do NOT screw up the electrical connections! Polarity is important. If you are not sure, figure it out first... trial and error testing can get expensive!

c) Do NOT exceed the maximum electrical specifications! Pay attention to the maximum allowable Voltage, Current and Wattage (Volts x Amps).

d) Do NOT use a propeller that is bigger in diameter and/or bigger in pitch than the specifications provided! Use the recommended propeller.

e) Do NOT overheat. Ensure adequate cooling by exposing the motor and entire ESC to moving air.

f) Do NOT operate the motor if the prop appears to wobble when you turn it by hand! Look at the back of the hub as you rotate the propeller over by hand. The back of the hub should remain in one plane throughout the rotation, not wobble.

g) Do NOT operate if the motor appears to vibrate! Look at the prop shaft when it first gets going. If it looks blurry to the eyes or sounds strange it is vibrating. Excessive vibration will destroy your motor and possibly hurt your servos as well. Stop and check all bolts for tightness and make sure the prop is turning true (no wobble) and that the prop is balanced.

h) Do NOT operate with loose fasteners! Check bolts, nuts, screws etc for snug tightness. Do not over tighten but keep them snug. Check periodically, particularly after the first few times you use the motor. Use blue thread locker such as Pacer Z42 to help keep fasteners from loosening up. If you find that fasteners are continously loosening up even after the motor has been used many times, you have a vibration issue. Check for sources of vibration. Excessive vibration will destroy your motor.

i) Do NOT operate at High Throttle on the ground or test bench for longer than 10 seconds! High Throttle static operation such as this where the airplane is not moving, induces maximum load on the motor while not providing proper air flow to help cool it. Heat will build up quickly, particularly if the motor is cowled. Heat is bad news. Heat can melt the windings down and quickly destroy the motor.

j) Do NOT operate without a safety fuse system!

k) Do NOT assume an electric motor is the same as a glow or gas engine! An electric motor is very different. Electric motors will attempt to overcome any load they encounter, even to the point of destroying themselves.

l) Do NOT use your plumbing tools or hammer! A brushless motor is not a farm tractor. Small hand tools only. Snugly tight does not mean you tighten things to the point they strip.

m) Do NOT get dirt, water or metal objects into the motor! If you drop a small screw or nut when working on your model, find it first before turning on your motor. Electric motors have strong magnets. Chances are that if you drop something small and metal into your model and can't find it... that it will be inside the motor. Turn the motor over by hand and pay attention to any unusual resistance, grinding or other odd sounds or feel. Find the missing metal item before operating your motor!

|

| 1.4.6.1.8. Support | On Line, eMail, Fax, Phone, Mail

|

| We offer the Best in Support Services. | We back up our products and our customers with the best support services available. From our industry leading Knowledge Base to information about your Shipment, we've got you covered!

To access our Support Services please:

Your Choice of Support Services that Work for You:

|

| 1.4.6.1.8.1. Contact Us | For Sales and other Inquiries

|

| Support - Contact Us - Reach our Sales Department by eMail, Fax, Phone or Mail | Technical Inquiries: Please review the information provided in our Knowledge Base. After checking our Knowledge Base, if you need further assistance please use our Submit A Question service to get a response within 2 Business Days. Sales Inquiries: Please note that our Sales Department personnel are trained and dedicated to:

- Helping you with non-technical pre-purchase questions,

- Helping you place your order,

- Pointing out any sales, combos or specials that you may wish to consider,

- Inputting your order to our computer system so that it ships out as accurately and quickly as possible... usually the same day,

- Resolving any invoicing problems, and

- Helping to sort out any missing shipment or shipment damage issues.

Their depth of technical knowledge is about on par with what is shown in our printed sales literature. In most cases, they are working from the same printed advertisements or content from our web site that you are. Asking sales personnel to confirm the size, color and availability of a product is well within their capabilities. However, asking detailed questions about technical issues is not.

Buy our Products:

For All Other Inquiries... please consult the following resources:

- On Line Information

- On Line Support Services

- After reviewing our On Line resources, if you require additional assistance please contact us by eMail, fax, phone or mail as follows:

- Ask a Question

- eMail

- Fax

- Phone

- Mail

- Richmond RC Supply Ltd, #114 - 7350 72nd Street, Delta, BC, V4G-1H9

- Mail & printed correspondence only.

- We are not able to accomodate personal site visits or drop-offs/pick-ups at this location.

- Please note that all inbound Shipments require pre-Authorization in advance.

- Unauthorized inbound shipments will be refused.

|

| 1.4.6.1.9. Keep Up to Date | Check Frequently for Updates |

| Support - Stay Current - Check Frequently for Updated &/or Additional Information | This information is subject to change without notice. When viewing this information in a printed form the printing date will be visible in the lower right corner. Check frequently for updates &/or Additional Information.at www.richmondrc.com, > Enter the Site, > Support Services, follow the links to our Knowledge Base. Review the Table of Contents and search for the name and/or part number of this product.

For automated notification of changes to information contained in our Knowledge Base please register as a Priority Response member and subscribe to our Priority Response Notification Service.

|

| 1.4.6.2. Power Module - #VMM-D210XPM1 For VMA-D210X DO27 - Additional Information | In general "Additional" Information is:

- In addition to that found in other documentation related to this product,

- Often reflects feedback &/or questions from users of the product.

Subject to the Conditions of Use, please review the attachments and related articles listed below. |

| COPYRIGHT | Copyright Richmond RC Supply Ltd. All rights reserved.

|

| Power Module Set - For VMAR Electric Models - Propeller Mounting |

VMAR Power Module Sets come with propeller mounting hardware that works with the propeller we recommend AND can be adapted to work with most other propellers.

a) We include the following: Three (3) 3 mm plain nuts, One (1) 3 mm security nut with fiber insert, Two (2) flat washers.

b) For propellers without a collet set and having a round hole in the back of the propeller hub that is bigger than the motor shaft or having a 3mm hexagonal recess in the back of the propeller hub: First thread one of the 3 mm plain nuts onto the shaft and position it about 3/4 in. (19 mm) from the open end of the shaft. Then install one flat washer followed by two of the 3 mm plain nuts (tighten snugly), then the prop, then a second flat washer and finally one of the 3 mm security nuts. Push the propeller towards the motor so that the two plain nuts are inserted into the recess in the back of the propeller hub and the back of the hub is against the adjacent flat washer. Tighten the 3 mm security nut so that the second flat washer is firmly in contact with the front of the propeller hub. In summary, the components are arranged as follows: Motor > 3 mm nut > flat washer > two (2) 3 mm nuts > propeller > flat washer > security nut.

c) For propellers with a collet set and having a larger recessed round hole in the back or front of the propeller hub that will accomodate a collet: Select a collet that has a center hole 3 mm (approx 1/8 in.) in diameter. Insert the collet into the hole in the propeller hub. From this point on treat the propeller and collet as one unit i.e. the "propeller". Next thread one of the 3 mm plain nuts onto the shaft and position it about 3/4 in. (19 mm) from the open end of the shaft. Then install one flat washer then the prop, then a second flat washer and finally one of the 3 mm security nuts. Push the propeller towards the motor so that the back of the propeller hub is against the adjacent flat washer. Tighten the 3 mm security nut so that the second flat washer is firmly in contact with the front of the propeller hub. In summary, the components are arranged as follows: Motor > 3 mm nut > flat washer > propeller > flat washer > security nut.

d) For propellers having a 3 mm (approx 1/8 in.) round hole that runs completely through the propeller hub with no other hole or recess in the back or front of the hub: Thread one of the 3 mm plain nuts onto the shaft and position it about 3/4 in. (19 mm) from the open end of the shaft. Then install one flat washer, then the prop, then a second flat washer and finally one of the 3mm security nuts. Push the propeller towards the motor so that the back of the hub is against the adjacent flat washer. Tighten the 3mm security nut so that the second flat washer is firmly in contact with the front of the propeller hub. In summary, the components are arranged as follows: Motor > 3mm nut > flat washer > propeller > flat washer > security nut.

e) For other propellers: We suggest obtaining a "squish" or "cinch" type propeller adapter suitable for 3mm shafts. You may wish to cut the motor shaft to a shorter length. Measure and test carefully before shortening the motor shaft with due consideration for any cowl and/or propeller clearance.

|

| 1.4.7. Power Module - For VMA-J210X JU52 Trimotor - Brushless Motor, ESC & Firewall |

| 1.4.7.1. Power Module - #VMM-J210XPM1 For VMA-J210X JU52 Trimotor - READ ME FIRST | PLEASE READ ME FIRST

BEFORE PROCEEDING TO ASSEMBLE OR OPERATE THIS PRODUCT

|

| LIABILITY DISCLAIMER & COPYRIGHT NOTICE | LIABILITY DISCLAIMER

The authors and/or suppliers and/or disseminaters of this information and/or product expressly disclaim any warranties or representations, either expressed or implied, including but not limited to implied warranties of fitness, accuracy, timeliness or applicability of the information and/or product provided here. In no event will the authors and/or suppliers and/or disseminaters of this information and/or product have any obligation arising from contract or tort, for loss of revenue or profit, or for indirect, special, incidental, consequential or other damages of any sort arising from this information and/or product. In using this information and/or product, the user accepts all responsibility for and all liability associated with such use.

PROCEEDING WITH THE USE OF THIS INFORMATION AND/OR PRODUCT INDICATES AGREEMENT WITH AND ACCEPTANCE OF THE LIABILITY DISCLAIMER.

|

| Please Note the following Caution | CAUTION

A Remote Control (RC) model aircraft is not a toy. It is a flying model that functions much like a full size airplane. If you do not assemble and operate model aircraft properly you can cause injury to yourself and others and damage property. DO NOT FLY a model aircraft unless you are qualified.

You are ultimately responsible for the mechanical, aeronautical and electrical integrity of any model you fly and all of the components that make up the model including but not limited to the airframe itself, control surfaces, hinges, linkages, covering, engine, motor, radio, servos, switches, wiring, battery and parts. Check all components before and after each flight. It is essential that you act with the clear understanding that you are solely responsible for all aspects of the model at all times. DO NOT FLY until it is right.

|

| When working with Batteries, Electric Models, Motors & Propellers, Chargers & Electrical Devices |

|

ALWAYS DISCONNECT THE BATTERY

or other electrical power source from any motor, device or charger when transporting, storing, not using or when you are not in attendance.

Keep hands, tools, clothing and all foreign objects well clear of equipment prior to and during operations. Take particular care to safeguard and protect your eyes and fingers and the eyes and fingers of other persons who may be nearby.

STAY CLEAR OF PROPELLER. PROTECT YOURSELF & OTHERS AT ALL TIMES

Use only a good quality propeller that has no cracks or flaws. Ensure propellers are securely attached. Stay clear of the propeller and stay clear of the plane of rotation defined by the propeller prior to connecting your battery to any motor or power system.

|

|

| 1.4.7.1.2. Power Module - For VMA-J210X JU52 Trimotor - General Information | |

|

| COPYRIGHT | Copyright Richmond RC Supply Ltd. All rights reserved.

|

| Tips for Avoiding Common Problems |

We have supplied thousands and thousands and thousands of model aircraft in the past 20 plus years. We're not bragging! We tell you this to give some credibility to our suggested list of tips that follow. In talking to modelers around the world, here is what we have found is the key to...

AVOIDING 90% of PROBLEMS that can arise:

- READ THE CAUTION ABOVE & READ THE LIABILITY DISCLAIMER.You are responsible for all aspects of any model you fly. You're It!

- READ ALL DOCUMENTATION before doing anything else!

- INSPECT CAREFULLY immediately upon arrival!.

- RETAIN ALL PACKAGING until the checkout is complete! If you need to return anything you must have all of the original packaging.

- READ & LOOK! At everything! Do it once & then do it again.

- REMEMBER WHAT "ARF" STANDS FOR. ARF means ALMOST Ready to Fly with an emphasis on ALMOST! Some assembly and modeling skills are required.

- ALLOW ENOUGH TIME to enjoy the assembly process! Rushing into a 6 hour job with 3 hours to spare simply will not work. This is a Hobby... take your time.

- DRY FIT & TEST ASSEMBLE EVERYTHING before you glue anything!

- USE 30 MINUTE EPOXY when joining wings & installing stabilizers and other structural components but only after you have dry fitted and test assembled the components without glue! Once parts are glued together they cannot be unglued and they cannot be returned or replaced without charge.

- PLAN AHEAD! BE CAREFUL! If you get into trouble, DON'T PANIC. Review everything again, talk it over with an experienced modeler and if still in difficulty consult our Support Services.

- TEST TEST!!! TUG TUG TUG!!! EVERYTHING... BEFORE & AFTER EACH FLIGHT! Your model may have been largely pre-constructed and may have pre-installed control rods, hinges, control surfaces and many other essential components. Hinges may have been pinned after they have been installed. However, you must double check every control surface and component before and after each flight. You and only you are responsible for the integrity of all components and the integrity of the model itself. Check everything before and after each flight. Tug on control surfaces, control rods, mounting bolts, T-nuts, mounting plates... tug on everything!

- DO NOT OVER TIGHTEN WING BOLTS or other fasteners. You want bolts and nuts snugly tight and if metal you can use a medium grade thread locker such as Pacer Z42 to help them stay tight. Fasteners must be snug and secure. However a model airplane is not a farm tractor or a garbage compactor. You do not need a pipe wrench or an electric drill to tighten up wing bolts or any other fastener. Leave your plumbing and power tools at home.. hand tools only and go easy on the torque... snug and secure... not stripped or torqued until they squeak or break. Wing bolts can take tremendous torque before breaking... but when you over tighten them or use an electric screw driver on a set of wing bolts, long before the bolts break you can fracture the fuselage, crack the mounting blocks or pull the heads of the bolts through the wing... these problems have a nasty habit of revealing themselves when you least expect the wing to fall off!

- DO NOT OVERPOWER ANY MODEL! Stay within the recommended power range for the model. If you overpower the model you run a high risk of structural failure that will lead to loss of control and a subsequent crash that will destroy the model and may cause injury and/or property damage.

- ASSUME NOTHING! Remember the old yarn about what happens when you ASS-U-ME something. Check everything repeatedly and frequently and DO NOT FLY any model unless you are satisfied that everything is in good working order.

|

| 1.4.7.1.3. Power Module - For VMA-J210X JU52 Trimotor - Introduction | |

Before beginning the Installation Instructions please read the Overview and check off the components provided. Each component is in a labelled parts bag. Please check off the components against the Contents list below. Leave the components in their parts bags for now. Do not remove the components from their parts bags until each is needed during the installation process.

|

| Power Module Set - For VMAR Electric Models - Overview | VMAR Power Module Sets are intended for modelers who already have their own Li Po Battery, Servos, Props and wiring systems but who wish to purchase an easy to install power system including the firewall(s), motor(s) and speed control(s) that have been factory designed for and tested with their VMAR model.

|

| 1.4.7.1.4. Power Module - For VMA-J210X JU52 Trimotor - Contents | This VMAX Power Module (#VMM-J210PM1) contains the following

- One (1) power pylon for the fuselage, consisting of:

- Laser cut wood fuselage power module firewall assembly (a component of #VMA-J210XPMV),

- Brushless Motor (#VMM-111B18VM),

- Pre-installed motor mounting fasteners,

- Propellor mounting hardware,

- Electronic Speed Control (ESC) (#VMC-120B15VC),

- Wiring between the Motor and the ESC,

- Wiring leads from the ESC to provide Positive (+) power, Negative (-) power and throttle control

- Two (2) power assemblies for the wings, each consisting of:

- Laser cut wood motor mounting plate (a component of #VMA-J210XPMV),

- Brushless motor (#VMM-111B18VM),

- Semi-installed motor mounting fasteners,

- Propellor mounting hardware,

- Electronic Speed Control (ESC) (#VMC-120B15VC) with mounting block secured by a zip strap,

- Wire extension set (3 wires) for each motor to provide electrical power between each wing motor and it's respective ESC,

- Wiring leads from the ESC to provide Positive (+) power, Negative (-) power and throttle control

- Crimp on bullet connectors (female) for the ESC power feeds (3 Red, 3 Black),

- All components have been factory connected & tested.

- Documentation

|

| 1.4.7.1.5. Power Module - For VMA-J210X JU52 Trimotor - Installation Instructions | |

Consult any labels carefully, particularly the larger WARNING labels. The labels are largely self explanatory. Reading the labels will save you a great deal of time and help prevent damage to your equipment.

|

| 1.4.7.1.5.1. Stage 1 - Install Power Pylons - For VMA-J210X JU52 Trimotor |

a) Review the Read Me First documentation and the Assembly & Operations Manual that came with your model.

b) Not Applicable

c) Complete Stage 1 from the Assembly & Operations Manual.

d) Complete Stage 2 from the Assembly & Operations Manual. Note that in some markets the power pylons have been pre-attached to the wing by the factory.

e) Once you completed Stage 2 from the Assembly & Operations Manual you will have an assembled wing with power pylons attached to the wing.

f) Complete Stages 3 to 8 from the Assembly & Operations Manual.

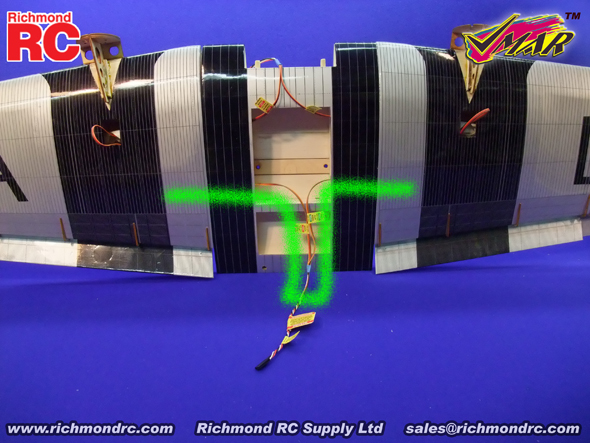

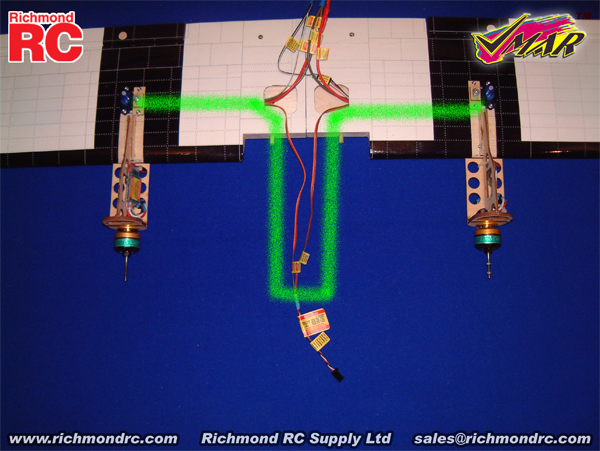

g) Review Stage 9 of the Assembly & Operations Manual. Skip step 9.1 and replace steps 9.2, 9.3 and 9.4 with the following procedure.

h) Look carefully at the wing power assemblies provided with this Power Module set. Consult figures 9C, 9E and 9F in the Assembly and Operations Manual provided with your model.

For each wing motor in turn,

i) Remove the four loosely fitted nut, bolt and washer sets from the wood motor mounting plate.

j) Remove the long black tapered head screws from the back of the wood motor mounting plate.

k) Fit the motor mounting plate (with motor) to the power pylon using the two long black taper head screws as shown in Figure 9E of the Assembly and Operations Manual. Leave slightly loose for now. Orient the mounting plate so that the motor wires will pass through the slot in the power pylon as shown in figure 9B, 9F and 9G of the Assembly and Operations Manual.

l) Insert the four nut, bolt and washer sets through the wood motor mounting plate and through the power pylon as depicted in Figure 9F of the Assembly and Operations Manual. We suggest having the nuts at the back of the pylon (opposite to that shown in Figure 9F).

m) Tighten the two long black taper head screws and the four nut and bolt sets and ensure the motor mounting plate is securely attached to the power pylon.

n) Apply medium strength (blue) thread locker such as Pacer Z42 to the nuts to prevent them from vibrating loose.

o) Repeat steps i) through n) for the second wing motor.

p) Install three (3) motor extension wires for each wing motor per Figures 9G and 9H of the Assembly and Operations Manual. Note that although the wires may appear to be the same color, there are labels near the female (motor) ends of each wire that direct which wire is to be attached to the red, black and white ESC wires respectively. WORK WITH ONE WIRE AT A TIME. Feed each wire separately from the motor pylon access holes in the upper surface of the wing. Feed the male end of each wire down through the access hole and into the wire guide tube until it exits the tube and enters the large access cavity at the center of the wing. Connect each motor extension wire to the appropriate speed control wire for each wing motor per Figure 9I of the Assembly and Operations Manual and per the label attached to the motor end of each extension wire. It is important to work with one wire at a time and to follow the intent of the labels.

In summary:

- The red ESC wire connects to the red motor wire.

- The black ESC wire connects to the white motor wire.

- The white ESC wire connects to the black motor wire.

r) Review Stage 9, Figures 9K, 9L and 9M and then secure the pre-assembled fuselage engine pylon to the fuselage.

|

| 1.4.7.1.5.2. Stage 2 - Install Electronic Speed Controls (ESC) - For VMA-J210X JU52 Trimotor |

a) Review the Read Me First documentation and the Assembly & Operations Manual that came with your model.

b) Not Applicable

c) Complete Stage 1 from the Assembly & Operations Manual.

d) Complete Stage 2 from the Assembly & Operations Manual. Note that in some markets the power pylons have been pre-attached to the wing by the factory.

e) Once you completed Stage 2 from the Assembly & Operations Manual you will have an assembled wing with power pylons attached to the wing.

f) Complete Stages 3 to 8 from the Assembly & Operations Manual.

g) Review Stage 9 of the Assembly & Operations Manual. In particular consult figure 9I of Assembly and Operations Manual. We suggest that in lieu of Figure 9I that you instead arrange the two wing ESC's as follows:

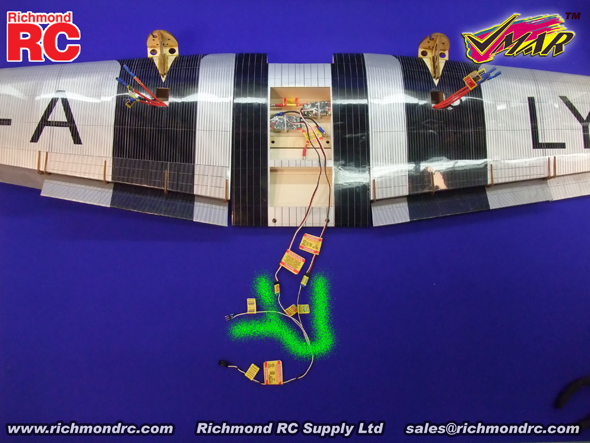

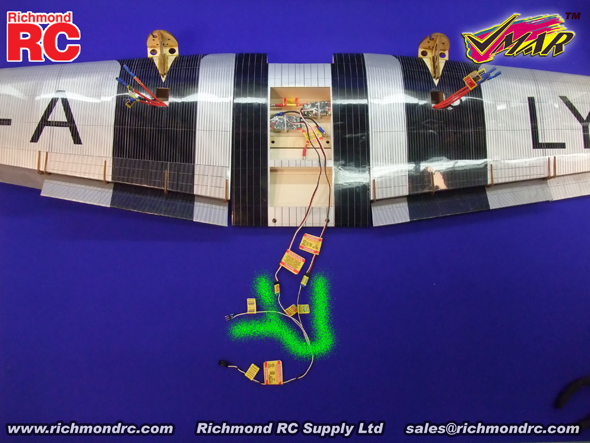

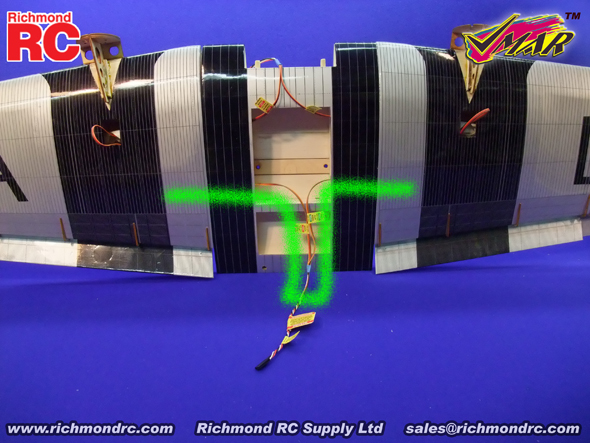

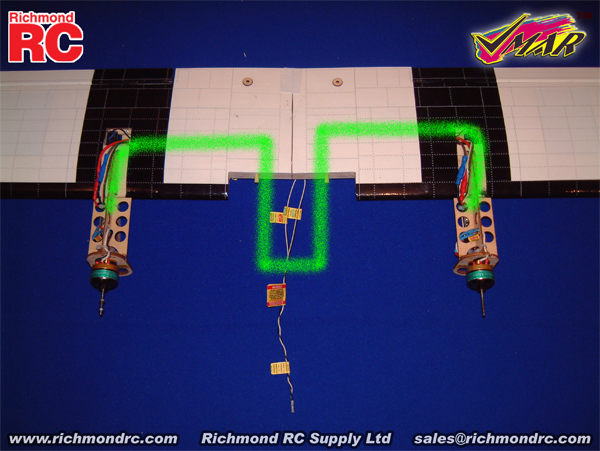

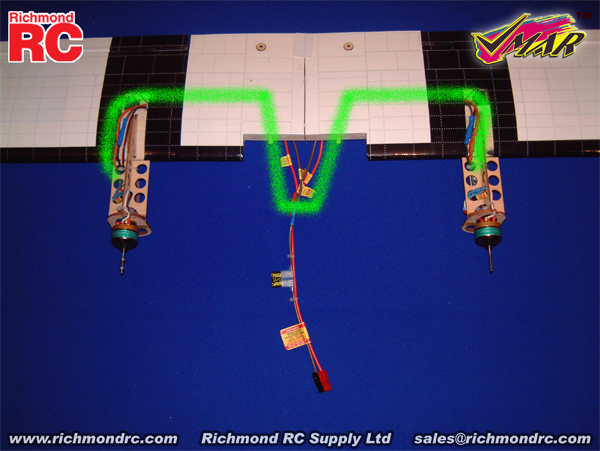

h) See Figure 2A. Note the orientation and position of the two speed controls. In particular note that the ends of the ESC with the motor power wires are partially positioned into the wing bay cavity adjacent to the large open cavity at the center of the wing.

i) You will find a wooden block with a slot, zip strapped to each wing ESC. AFTER installing all wiring and before flying your model, use ZAP-A-GAP or ZEPOXY to attach the blocks to the floor of the large cavity at the center of the wing, oriented and positioned as shown in Figure 2A. If you need to remove the ESC's at a later date you can cut the zip strap to remove the ESC and then re-install the ESC using a new zip strap.

|

| 1.4.7.1.5.3. Stage 3 - Power Module Wiring - For VMA-J210X JU52 Trimotor |

a) Review the Read Me First documentation and the Assembly and Operations Manual that came with your model. Continue with the assembly procedures provided therein.

b) When you are ready to complete Stage 9 of the Assembly and Operations Manual pause and review Figure 9N and these notes carefully.

c) Stage 9 of the Assembly and Operations Manual covers the installation of the electric motors and speed controls. In effect by purchasing a VMAX Power Module you have avoided much of this work and in earlier stages of these instructions pertaining to this VMAX Power Module you have installed the factory assembled power pylons to the wing and the fuselage and extended the wiring from the wing motors to their respective speed controls in the center section of the wing.

d) You will need to complete the wiring.

- If you have purchased the VMAR Wiring Harness Set for this model (VMA-J210XWHS) please see the detailed wiring instructions provided therein.

- If you do NOT have the VMAR Wiring Harness Set for this model you will need to use your own wiring setup. Make sure whatever you do is compatible with your radio system, your servos, your battery and the speed controls.