| 1. Power Module Set - For VMA-P210X PC9 & Texan II - Brushless Motor, ESC & Firewall |

VMM-P210XPM1 POWER MODULE SET

|

| 1.1. Power Module Set - #VMM-P210XPM1 For VMA-P210X PC9 & Texan II - READ ME FIRST | |||||||||

| |||||||||

| LIABILITY DISCLAIMER & COPYRIGHT NOTICE |

LIABILITY DISCLAIMER The authors and/or suppliers and/or disseminaters of this information and/or product expressly disclaim any warranties or representations, either expressed or implied, including but not limited to implied warranties of fitness, accuracy, timeliness or applicability of the information and/or product provided here. In no event will the authors and/or suppliers and/or disseminaters of this information and/or product have any obligation arising from contract or tort, for loss of revenue or profit, or for indirect, special, incidental, consequential or other damages of any sort arising from this information and/or product. In using this information and/or product, the user accepts all responsibility for and all liability associated with such use. PROCEEDING WITH THE USE OF THIS INFORMATION AND/OR PRODUCT INDICATES AGREEMENT WITH AND ACCEPTANCE OF THE LIABILITY DISCLAIMER.

|

| Please Note the following Caution |

CAUTION A Remote Control (RC) model aircraft is not a toy. It is a flying model that functions much like a full size airplane. If you do not assemble and operate model aircraft properly you can cause injury to yourself and others and damage property. DO NOT FLY a model aircraft unless you are qualified. You are ultimately responsible for the mechanical, aeronautical and electrical integrity of any model you fly and all of the components that make up the model including but not limited to the airframe itself, control surfaces, hinges, linkages, covering, engine, motor, radio, servos, switches, wiring, battery and parts. Check all components before and after each flight. It is essential that you act with the clear understanding that you are solely responsible for all aspects of the model at all times. DO NOT FLY until it is right.

|

| 1.1.1. Think Safety |

| When working with Batteries, Electric Models, Motors & Propellers, Chargers & Electrical Devices | |

|

| 1.1.2. Power Module Set - For VMA-P210X PC9 & Texan II - General Information |

|

| COPYRIGHT |

Copyright Richmond RC Supply Ltd. All rights reserved.

|

| Tips for Avoiding Common Problems |

We have supplied thousands and thousands and thousands of model aircraft in the past 20 plus years. We're not bragging! We tell you this to give some credibility to our suggested list of tips that follow. In talking to modelers around the world, here is what we have found is the key to... AVOIDING 90% of PROBLEMS that can arise:

|

| 1.1.3. Power Module Set - For VMA-P210X PC9 & Texan II - Introduction |

Before beginning the Installation Instructions please read the Overview and check off the components provided. Each component is in a labelled parts bag. Please check off the components against the Contents list below. Leave the components in their parts bags for now. Do not remove the components from their parts bags until each is needed during the installation process.

|

| Power Module Set - For VMAR Electric Models - Overview |

VMAR Power Module Sets are intended for modelers who already have their own Li Po Battery, Servos, Props and wiring systems but who wish to purchase an easy to install power system including the firewall(s), motor(s) and speed control(s) that have been factory designed for and tested with their VMAR model.

|

| 1.1.4. Power Module Set - For VMA-P210X PC9 & Texan II - Contents |

This VMAX Power Module Set (#VMM-P210XPM1) consists of the following components:

|

| Power Module Set - For VMAR Electric Models - Typical Contents |

VMAR Power Module Sets are factory designed for each VMAR Electric Model and contain the firewall(s), electric motor(s) and electronic speed controls(s) (ESC) for the applicable model. A VMAX Power Module Set typically consists of the following components:

Power Module Sets for Multi-Motor Models:

VMAR Power Module Sets do NOT include:

These components are NOT included in the Power Module Set and will be needed to complete your model. If you do not already have these items, they will need to be obtained separately.

|

| 1.1.5. Power Module Set - For VMA-P210X PC9 & Texan II - Installation Instructions |

Consult any labels carefully, particularly the larger WARNING labels. The labels are largely self explanatory. Reading the labels will save you a great deal of time and help prevent damage to your equipment.

|

| 1.1.5.1. Power Module Set for VMA-P210X PC9 & Texan II - Installation Procedure |

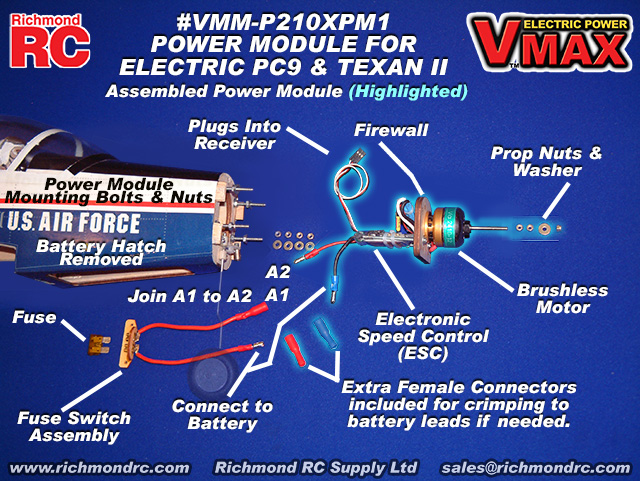

The following depiction illustrates the Fuselage and the assembled Power Module and how it is wired to the Fuse Assembly and Battery Pack:

|

| VMA-P210X PC9 & Texan II 06-12 ARF - Firewall (Power Module) Spacing - Page 7, Figure 11K |

This supplementary information applies to manuals with a copyright date of 20070418 (see back cover). Manuals having later copyright dates may already reflect this supplementary information. Please see Page 7, Figure 11K. Figure 11K illustrates the spacing between the fixed firewall in the front of the fuselage and the power module firewall to which is attached the motor and speed control.

The picture is correct. However the black type annotated distance shown in Figure 11K of the 20060314 version of the manual is incorrect. The distance should be .5 in. (12.5 mm). The actual distance is not particularly critital. What is important is that:

|

| 1.1.6. Power Module Set - For VMA-P210X PC9 & Texan II - Operating |

Consult any labels carefully, particularly the larger WARNING labels. The labels are largely self explanatory. Paying attention to the operating limits will help prevent damage to your equipment.

We developed this Power Module as a "system" suitable for your model. We strongly advise against changing any component within this system. If a component requires replacement, ensure you replace it with a new but identical component to that which is being swapped out.

|

| 1.1.6.1. Propellers - Power Module Operations - VMA-P210X PC9 & Texan II |

|

| 1.1.6.2. On the Ground - Power Module Operations - For VMA-P210X PC9 & Texan II |

Operating the brushless motor on the ground or in a static mode whereby the aircraft cannot move, puts peak loads on the motor while not providing adequate cooling normally generated in flight. Peak loads coupled with inadequate air flow leads to very rapid heat buildup within the brushless motor that can damage or destroy the motor very quickly.

ENSURE ADEQUATE COOLING. DO NOT OPERATE AT HIGH THROTTLE ON THE GROUND FOR LONGER THAN 10 SECONDS.

|

| 1.1.6.3. Powering Up - Power Module Operations - VMA-P210X PC9 & Texan II |

|

| 1.1.6.4. Motor Power Auto-Cutoff - Power Module Operations - VMA-P210X PC9 & Texan II |

The Electronic Speed Control (ESC) has an embedded "auto-cutoff" controller that will reduce battery power supplied to the motor as the battery reserve begins to run out. This auto-cutoff controller ensures that the battery retains sufficient energy to power the receiver and servos. As the energy reserve in the battery approaches "empty", the auto-cutoff begin to reduce power available for the motor while allocating the remaining energy to provide power for the receiver and servos so that you can maintain flight control using the remaining energy.

Land immediately when you detect that the motor power is beginning to fade. Once the power begins to fade, you have a very short time remaining before the ESC will auto-cutoff power to the motor.

|

| 1.1.7. Power Module Set - For VMA-P210X PC9 & Texan II - No No's & Must Do's |

| Motors - No No's - That can Destroy Your Motor |

Question: Are there any No No's that I should be careful to stay clear of when running my Brushless Motor? Answer: We have sold many many brushless motors. From the questions and service requests we get we can pretty well sum up the No No's and Must Do's as follows:

|

| 1.1.8. Support |

On Line, eMail, Fax, Phone, Mail |

| We offer the Best in Support Services. |

We back up our products and our customers with the best support services available. From our industry leading Knowledge Base to information about your Shipment, we've got you covered!

To access our Support Services please:

Your Choice of Support Services that Work for You:

|

| 1.1.8.1. Contact Us |

For Sales and other Inquiries |

| Support - Contact Us - Reach our Sales Department by eMail, Fax, Phone or Mail |

Technical Inquiries: Please review the information provided in our Knowledge Base. After checking our Knowledge Base, if you need further assistance please use our Submit A Question service to get a response within 2 Business Days.

Sales Inquiries: Please note that our Sales Department personnel are trained and dedicated to:

Their depth of technical knowledge is about on par with what is shown in our printed sales literature. In most cases, they are working from the same printed advertisements or content from our web site that you are. Asking sales personnel to confirm the size, color and availability of a product is well within their capabilities. However, asking detailed questions about technical issues is not.

Buy our Products:

For All Other Inquiries... please consult the following resources:

|

| 1.1.9. Keep Up to Date |

Check Frequently for Updates |

| Support - Stay Current - Check Frequently for Updated &/or Additional Information |

This information is subject to change without notice. When viewing this information in a printed form the printing date will be visible in the lower right corner. Check frequently for updates &/or Additional Information.at www.richmondrc.com, > Enter the Site, > Support Services, follow the links to our Knowledge Base. Review the Table of Contents and search for the name and/or part number of this product.

For automated notification of changes to information contained in our Knowledge Base please register as a Priority Response member and subscribe to our Priority Response Notification Service.

|

| 1.2. Power Module Set - #VMM-P210XPM1 For VMA-P210X PC9 & Texan II - Additional Information |

In general "Additional" Information is:

Subject to the Conditions of Use, please review the attachments and related articles listed below. |

| COPYRIGHT |

Copyright Richmond RC Supply Ltd. All rights reserved.

|

| Power Module Set - For VMAR Electric Models - Propeller Mounting |

VMAR Power Module Sets come with propeller mounting hardware that works with the propeller we recommend AND can be adapted to work with most other propellers.

a) We include the following: Three (3) 3 mm plain nuts, One (1) 3 mm security nut with fiber insert, Two (2) flat washers.

b) For propellers without a collet set and having a round hole in the back of the propeller hub that is bigger than the motor shaft or having a 3mm hexagonal recess in the back of the propeller hub: First thread one of the 3 mm plain nuts onto the shaft and position it about 3/4 in. (19 mm) from the open end of the shaft. Then install one flat washer followed by two of the 3 mm plain nuts (tighten snugly), then the prop, then a second flat washer and finally one of the 3 mm security nuts. Push the propeller towards the motor so that the two plain nuts are inserted into the recess in the back of the propeller hub and the back of the hub is against the adjacent flat washer. Tighten the 3 mm security nut so that the second flat washer is firmly in contact with the front of the propeller hub. In summary, the components are arranged as follows: Motor > 3 mm nut > flat washer > two (2) 3 mm nuts > propeller > flat washer > security nut.

c) For propellers with a collet set and having a larger recessed round hole in the back or front of the propeller hub that will accomodate a collet: Select a collet that has a center hole 3 mm (approx 1/8 in.) in diameter. Insert the collet into the hole in the propeller hub. From this point on treat the propeller and collet as one unit i.e. the "propeller". Next thread one of the 3 mm plain nuts onto the shaft and position it about 3/4 in. (19 mm) from the open end of the shaft. Then install one flat washer then the prop, then a second flat washer and finally one of the 3 mm security nuts. Push the propeller towards the motor so that the back of the propeller hub is against the adjacent flat washer. Tighten the 3 mm security nut so that the second flat washer is firmly in contact with the front of the propeller hub. In summary, the components are arranged as follows: Motor > 3 mm nut > flat washer > propeller > flat washer > security nut.

d) For propellers having a 3 mm (approx 1/8 in.) round hole that runs completely through the propeller hub with no other hole or recess in the back or front of the hub: Thread one of the 3 mm plain nuts onto the shaft and position it about 3/4 in. (19 mm) from the open end of the shaft. Then install one flat washer, then the prop, then a second flat washer and finally one of the 3mm security nuts. Push the propeller towards the motor so that the back of the hub is against the adjacent flat washer. Tighten the 3mm security nut so that the second flat washer is firmly in contact with the front of the propeller hub. In summary, the components are arranged as follows: Motor > 3mm nut > flat washer > propeller > flat washer > security nut.

e) For other propellers: We suggest obtaining a "squish" or "cinch" type propeller adapter suitable for 3mm shafts. You may wish to cut the motor shaft to a shorter length. Measure and test carefully before shortening the motor shaft with due consideration for any cowl and/or propeller clearance.

|